WA Machinery Glass automates their glass processing

with a waterjet cutting system

GLASS

Offer a unique service with new technology

Improve flexibility to diversify the customers

Secure larger contracts

Optimized production process

Ability to process virtually any type of material

Ability to produce more complex geometries, and replicate them with ease

Industry of Reference and Services

WA Machinery Glass is a mobile glass replacement service covering the greater Perth area. They are a family owned and operated business and have been servicing the mining/earthmoving industry for over 20 years. WA Machinery Glass can process any of the following:

- Earthmoving/machinery glass replacement

- Mining machinery glazing and glass replacement

- Truck/heavy haulage glass replacement

- Commercial automotive windscreens including sides and rears

- XIR® Fortress/solar control glass

- Window tinting/safety films-machinery & motor vehicles laminated glass-flat

- Clear/green glass can be cut to size/shape as required

- Window Tinting

What Prompted WA Machinery Glass to Techni Waterjet

For more than 20 years, Wayne Barnett and son Tyson (Owners of WA Machinery Glass) constantly look for new and innovative machinery to keep the business ahead of the competitors.

“We came across waterjet as a method for automating our operations. We already knew that one of the biggest advantages of waterjet cutting is the ability to cut complex applications and virtually all materials.

– Tyson Barnett, Co-Owner of WA Glass.

Therefore, after extensive research, WA Machinery Glass purchased their first Techni Waterjet® Intec™G2 612 (1.8 x 3.6 meter) accompanied with the Quantum® VP15/52 Electric Servo Pump. Wayne had some reasons in mind why he selected Techni.

A Huge Step Forward

WA glass would cut the glass painstakingly by hand which had resulted in one-to-many problems. Firstly, the handling of the glass would add unnecessary time to the process and secondly there were an added cost to glass breakage. Automating and streamlining the process was crucial to their thinking and the waterjet system and in particular the software was the answer.

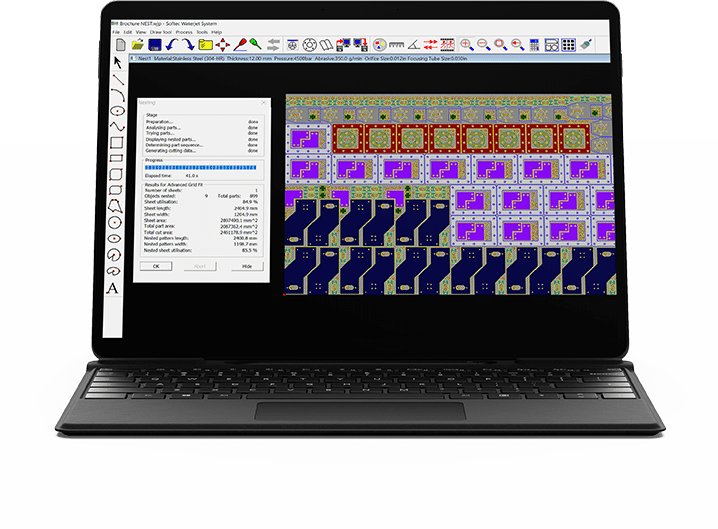

Thanks to proprietary Softec NEST™ nesting software, TECHNI demonstrated how the machine could have allowed WA Machinery Glass to nest more parts per sheet and reduce programming time, saving them thousands of dollars per year. The nesting software utilizes advanced nesting algorithms developed by Geometric Global which is specifically developed to maximize the production while leaving minimum scrap material..

“The nesting feature enabled us to increase our yield even further therefore the cutting process was further streamlined.

– Said Tyson.

Techni Technology Key Advantage

Wayne and Tyson selected waterjet and Techni for that system was due to the efficiency of the Quantum VP electric servo pump.

“A dilemma we faced was that our factory had limiting power supply though. Luckily, Techni’s revolutionary Quantum VP pump only runs 22 AMP full load which lowers the need for higher power supply.

– Said Tyson.

The VP pump also greatly reduces the power bills as less power is required to run in comparison to traditional pumps on the market such as intensifier pumps.

To learn more please visit WA Machinery Glass Facebook page.