When it comes to cutting multiple layers of different materials, using a technology that streamlines the process is key to improving efficiency. Instead of cutting each layer individually, why not cut them all at once with precision?

This is where waterjet technology shines. By harnessing high-pressure water streams combined with abrasive particles, waterjet cutting allows manufacturers to achieve cleaner cuts with greater ease. Plus, one of its biggest advantages is that it eliminates the risk of thermal damage, making it an increasingly popular choice for many industries.

In this guide, we will explore the capability of waterjet cutting systems in processing stacked materials and provide detailed insights into the process and benefits.

Can You Cut Stacked Materials with Waterjet Technology?

Yes, stacked materials can be cut effectively using waterjet technology. Waterjet cutting systems are designed to handle multiple layers of various materials, making them an ideal solution for cutting stacked materials such as metals, glass, composites, and plastics.

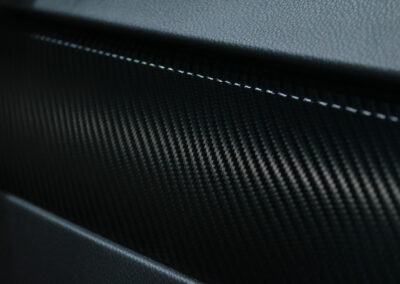

The ability to cut through different materials in one pass, without generating heat or distorting the material, makes waterjet machines a preferred choice for high-precision applications. Whether you’re working with carbon fiber, aluminum, or other materials, the versatility of waterjet systems allows you to maintain edge quality and accuracy.

What are the Benefits of Cutting Stacked Materials with a Waterjet?

Cutting stacked materials with waterjet technology offers a range of advantages, making it a highly efficient and precise method for many industries. This process not only improves productivity but also ensures high-quality results with minimal material wastage. Below is a detailed list of the primary benefits of using waterjet technology for cutting stacked materials.

- Provide Superior Edge Quality: Waterjet cutting offers excellent edge quality without the rough edges or burrs that are common with other cutting methods. This superior edge finish is particularly beneficial when cutting materials like metals, composites, and plastics, as it minimizes the need for secondary finishing.

- Provide Minimal Kerfs: One of the significant advantages of waterjet systems is the minimal kerf width they produce. The precision of waterjet cutting ensures that material wastage is kept to a minimum, as only a small amount of material is removed during the cutting process. This allows for better material utilization and cost savings.

- Provide Increased Productivity, Fast Cutting, and High-Quality Parts: Waterjet machines are designed to cut through stacked materials quickly and efficiently, enhancing overall productivity. Despite the fast cutting speed, the quality of the parts remains high, with precision cutting ensuring each part meets the required specifications.

- Provide Incredible Detail with Minimal Kerf: Waterjet systems can produce intricate designs and detailed cuts, even when working with stacked materials. The combination of precision and minimal kerf allows for complex patterns without compromising the integrity of the materials.

- Provide Raw Material Savings with Reduced Scrap: By optimizing material utilization and minimizing waste, waterjet cutting helps reduce scrap, leading to cost savings. This is especially important when working with expensive materials like carbon fiber or metals, where maximizing the use of each sheet is crucial.

- Provide Minimal Part Clamping with Minimal Lateral or Vertical Forces: Unlike other cutting methods that require extensive clamping to hold materials in place, waterjet cutting applies minimal lateral or vertical forces. This reduces the need for heavy clamping equipment and minimizes the risk of material shifting during the cutting process, which could compromise precision.

- Provide Single-Pass Cutting, Depending on Material Thickness: In many cases, waterjet machines are capable of cutting through multiple layers of stacked materials in a single pass. The ability to cut through various material thicknesses efficiently reduces overall cutting time and enhances throughput.

- Provide Cost Savings: Waterjet cutting delivers cost savings in several ways, including reduced material wastage, faster production times, and lower energy consumption compared to thermal cutting methods. The absence of heat also eliminates the need for expensive cooling systems, further reducing operational costs.

- Provide No Thermal Damage: Because waterjet cutting is a cold-cutting process, it does not generate heat during the cutting operation. This eliminates the risk of thermal damage, which can be a concern with other cutting methods, especially when working with heat-sensitive materials like plastics, composites, and metals.

- Provide Net or Near-Net Cutting, Requiring Little or No Hand Finishing: Waterjet cuts are highly precise, often resulting in net or near-net shapes that require little to no additional hand finishing. This further reduces production time and labor costs, making the overall process more efficient.

What is the Process of Cutting Stacked Materials with Waterjet?

Cutting stacked materials with waterjet technology is a highly efficient method that allows for precision cutting through multiple layers of various materials simultaneously. The process of cutting stacked materials with a waterjet involves several stages that ensure accuracy, minimal material wastage, and optimal results.

- Material Selection and Preparation: The first step in the cutting process involves selecting the appropriate materials for stacking. Once the materials are selected, they are cleaned and prepared to ensure no debris interferes with the cutting process.

- Stacking and Alignment: After selecting the materials, they are carefully stacked. Proper alignment is essential to ensure that the waterjet can penetrate through all the layers without deviation. Misaligned materials may result in inaccurate cuts, leading to production errors or material wastage.

- Securing the Stack: Once the materials are stacked and aligned, they need to be secured in place using minimal clamping or fixturing. This step prevents the stack from shifting during the cutting process, which can negatively affect the precision of the waterjet cuts.

- Setting Up the Waterjet Machine: The next stage involves setting up the waterjet machine. Parameters like water pressure, abrasive mix, and nozzle size are adjusted based on the thickness and type of stacked materials. For instance, higher pressures may be required for cutting through thicker materials or harder substances like metals.

- CNC Programming and Path Setup: Once the machine is configured, the cutting path is programmed using CNC (Computer Numerical Control) software. The CNC program ensures that the waterjet follows the exact pattern and dimensions required for the job, maintaining precision across all layers.

- Initiating the Cutting Process: With everything set up, the waterjet cutting process begins. The high-pressure stream of water mixed with abrasives is directed through the nozzle, cutting through the stacked materials. The cutting process can handle multiple layers in one pass, depending on material thickness, optimizing material utilization.

- Inspection and Quality Control: After the cutting process is complete, the stack is inspected to ensure the cuts meet the required specifications. Any necessary adjustments or minor refinements can be made during this stage to ensure that the products are up to standard.

- Post-Cut Processing and Finishing: Depending on the material and the intended use of the parts, additional finishing steps may be required. However, waterjet technology often results in clean, net or near-net cuts, minimizing the need for extensive post-processing.

What is the Optimal Stack Height and Material Configuration?

The optimal stack height for waterjet cutting depends on various factors, including material thickness, type, and the capacity of the waterjet machine. Here are the four most important factors:

- Material Type: Different materials have different cutting behaviors. Softer materials like foam or rubber may allow for taller stacks, while harder materials like aluminum or steel might require lower stacks to maintain precision.

- Material Thickness: The thickness of each individual material in the stack also affects the optimal height. For thin materials like sheets of metal or composites, higher stacks are manageable. However, cutting thicker materials may require reducing the stack height to maintain edge quality and cutting accuracy.

- Machine Capacity: Waterjet machines vary in power and capability. Machines with higher pressure and advanced cutting heads can handle thicker and taller stacks, but exceeding the machine’s capacity may lead to inefficiencies or cutting errors.

- Cutting Speed: The speed of the cutting process can impact the optimal stack height. Cutting too quickly through thick stacks might compromise the cut quality, leading to tapering or imprecise cuts. Adjusting the speed based on material configuration is essential for precision.

What Are the Potential Risks with High Stack Thickness?

While waterjet cutting is highly effective for stacked materials, there are several risks associated with cutting high stack thicknesses. Four of those risks are:

- Tapering: One of the primary risks is tapering, where the cut becomes narrower at the bottom of the stack than at the top. This occurs when the waterjet stream loses intensity as it travels through thicker materials. To reduce tapering, adjusting the water pressure or cutting speed can help maintain consistent cut quality across the stack. A 5-axis cutting head can also help with taper compensation by slightly tilting the jet stream.

- Misalignment of Layers: With high stack thicknesses, any misalignment becomes more pronounced, which can result in uneven cuts. Ensuring precise stacking and securing the layers properly before cutting is critical to avoid this issue.

- Reduced Cutting Efficiency: As the stack height increases, the efficiency of the waterjet system may decrease, especially when cutting hard materials like metals. This can lead to slower cutting times and potential wear on the waterjet machine’s cutting head and nozzle. Reducing the stack height or using a higher pressure setting can help mitigate this risk.

- Material Waste: In some cases, thicker stacks can result in material wastage if the cutting process isn’t carefully managed. Improper pressure settings or misalignment can lead to off-spec cuts, requiring rework or scrap, which affects production efficiency.

How to Select the Best Materials for Stacking?

Selecting the right materials for stacking is essential for achieving optimal results with waterjet cutting. The ideal materials for this process share certain characteristics that make them suitable for cutting stacked layers with precision. These materials should be compatible with the waterjet process, ensuring smooth cutting without compromising quality.

- Consistency in Material Thickness: One of the key factors in selecting materials for stacking is ensuring that the thickness of each layer is consistent. Whether you are cutting metal, composites, or glass, maintaining uniform thickness ensures that the waterjet machine can cut through each layer evenly, improving both precision and efficiency.

- Material Strength: The material should be strong enough to withstand the force of waterjet cutting without deforming or breaking. Metals such as aluminum and stainless steel are commonly used, as well as robust composites like fiberglass or carbon fiber.

- Compatibility with Abrasive Waterjet: Materials selected for waterjet cutting should be able to handle the abrasive nature of the process. Softer materials like foam or certain plastics may not stack well with harder materials like metal, and their selection needs to be carefully considered.

- Minimal Material Wastage: Ideal materials should allow for precise cutting with minimal kerf width. This characteristic reduces scrap and ensures better material utilization, which is a significant benefit when cutting stacked materials.

Techniques for Stacking Different Materials

When stacking different materials for waterjet cutting, proper techniques must be followed to ensure alignment and precision across all layers.

Each type of material may behave differently when exposed to the high-pressure waterjet, so it’s important to handle stacking with care. Below is a step-by-step guide for effectively stacking various material types for waterjet cutting:

- Ensure Compatibility: Before stacking, ensure that the materials you are cutting are compatible with each other.

- Align Each Layer Accurately: Proper alignment of all stacked materials is essential. Misaligned materials can result in uneven cuts and poor-quality parts. Use tools like alignment pins or fixtures to keep the layers perfectly stacked throughout the process.

- Secure the Stack: Lightly clamp or secure the materials to prevent movement during the cutting process. While waterjet systems apply minimal force, any shift in the stack could affect precision cutting. Make sure not to over-clamp, as this can cause distortion, especially with softer materials.

- Set the Optimal Stack Height: Depending on the materials and thicknesses, the optimal stack height needs to be determined. Thinner materials like metal sheets can be stacked higher, while thicker or more delicate materials might require lower stacks to ensure precision.

- Adjust the Waterjet Machine Settings: After stacking, set up the waterjet machine with the appropriate pressure and abrasive mix for the material types. The cutting head and nozzle should be chosen based on the hardness and thickness of the materials.

- Run a Test Cut: Before starting the full cut, perform a small test cut to check the settings and ensure all materials are being cut evenly. Adjustments can be made if necessary to achieve optimal results.

- Monitor the Cutting Process: Throughout the process, monitor the cutting head, water pressure, and alignment to ensure the stack remains stable and each layer is cut precisely.

What are Key Technical Considerations When Cutting Stacked Materials with Waterjet?

When cutting stacked materials with waterjet technology, several technical factors must be carefully considered to ensure precision and efficiency. These include selecting the right water pressure, nozzle type, and optimizing the cutting speed in relation to the material stack height.

Properly managing these variables helps to maintain edge quality, minimize material wastage, and produce consistent results across different materials.

Choosing the Right Water Pressure and Nozzle

Water pressure and nozzle selection directly impact the quality and precision of waterjet cuts. The combination of pressure and nozzle size must be adjusted based on the type and thickness of the stacked materials.

- Water Pressure: Higher water pressure is necessary for cutting thicker or denser materials like metals, but it needs to be balanced to avoid excessive wear on the waterjet cutting head. For cutting softer materials or thinner stacks, lower pressure settings may suffice. The pressure must be adjusted to penetrate through all layers of the stack evenly without causing tapering or loss of precision.

- Nozzle Selection: The nozzle controls the width of the cut (kerf) and influences the cutting speed. A smaller nozzle provides more precision but may cut slower, while larger nozzles increase cutting speed but reduce accuracy. Nozzles should be selected based on the material’s thickness and the complexity of the cut. For example, cutting thin sheets of materials like carbon fiber or aluminum requires a smaller nozzle for detailed work, while thicker materials like steel may need a larger nozzle.

Determining the Best Stack Thickness/Cutting Speed Combination

Balancing stack thickness and cutting speed is crucial to achieving optimal waterjet cutting results. The cutting speed needs to be adjusted based on the material’s thickness and type, as well as the height of the stack.

- Stack Thickness: Stacking thicker materials requires slower cutting speeds to maintain precision. For instance, when cutting a stack of thick metal sheets, the waterjet needs more time to penetrate each layer fully. On the other hand, thinner materials like plastics or composites may allow for faster cutting speeds while still maintaining quality.

- Cutting Speed: Faster cutting speeds can result in lower edge quality, particularly when dealing with complex designs or harder materials. Slowing down the cutting process ensures cleaner edges and reduces the risk of tapering, where the bottom layer is cut narrower than the top.

What Are the Challenges in Cutting Stacked Materials with Waterjet?

Waterjet cutting stacked materials offers a highly precise method, but it comes with specific challenges that can impact the quality and efficiency of the process. These challenges mainly stem from issues related to material alignment, tapering, and varying material thicknesses within the stack. Below are the most common challenges encountered during waterjet cutting and practical solutions to address them.

Varying Material Properties

Different materials have varying hardness, thickness, and compositions. When stacked, these differences can lead to inconsistent cutting quality. For instance, harder materials may take longer to cut, causing softer materials in the same stack to be overcut or damaged.

Solution: When cutting stacked materials of different types, arrange the materials in an order that places harder materials at the top of the stack. This helps to reduce cutting errors and ensures each material is processed at the right intensity.

Tapering

One of the most frequent challenges is tapering, where the waterjet cut is wider at the top and narrower at the bottom of the material. This happens due to the natural dispersion of the waterjet stream as it cuts through multiple layers, leading to inconsistent part dimensions.

Solution: Adjusting the water pressure and nozzle size can help reduce tapering. Lowering the water pressure slightly and using a smaller nozzle creates a more focused stream, which minimizes this effect. Additionally, slowing down the cutting speed can further improve edge precision, especially when dealing with thicker stacks. Use of a 5-axis head

Material Movement

In a stack, if materials are not properly secured, they can shift during the cutting process. This misalignment causes issues like incomplete cuts or deformed edges. Material movement is more common when cutting thinner or lightweight materials like plastics or carbon fiber.

Solution: Using minimal but effective clamping or fixturing methods to secure the stacked materials can prevent movement during the cutting process. Ensure that the materials are aligned correctly before cutting begins to maintain consistent cuts across all layers.

Piercing Issues

Piercing through stacked materials can lead to chipping or damage at the entry point, especially for brittle materials such as glass or composites. This can result in substandard parts that require additional finishing or reworking.

Solution: Pre-drilling pilot holes or using a slower waterjet speed when piercing stacked materials helps to avoid material damage at the point of entry. This reduces the force exerted on the material, creating a cleaner entry point and preserving material integrity.

Handling V-Shaped Tapers

V-shaped tapering occurs when the cut widens at the top of the stack and narrows toward the bottom. This issue is particularly common when cutting thicker or harder materials with a waterjet, as the water stream begins to diverge as it penetrates through each layer. Here are strategies to minimize or prevent V-shaped tapering during waterjet cutting.

- Adjust Water Pressure: One of the simplest ways to reduce tapering is by adjusting the water pressure. High water pressure can increase the cutting speed but also widens the cut, especially at the top of the material. Reducing the pressure slightly allows the waterjet to cut more evenly through each layer of the stack, reducing the tapering effect.

- Optimize Nozzle Angle and Size: The angle and size of the nozzle can influence the extent of tapering. A smaller nozzle provides a more concentrated stream, which is better for cutting thicker materials. In some cases, tilting the nozzle slightly (known as dynamic waterjet cutting) can help offset the tapering by creating a more consistent cut from top to bottom. Even better, use a 5-axis waterjet system if possible.

- Control Cutting Speed: Slower cutting speeds tend to produce cleaner and more precise cuts. By reducing the cutting speed, the waterjet has more time to penetrate each layer of the stacked material, leading to a more uniform cut and reducing taper. This method is particularly effective when cutting dense materials like metal.

- Utilize Specialized Waterjet Software: Advanced waterjet systems often come with software designed to account for tapering during the cutting process. This software automatically adjusts the cutting speed, nozzle angle, and pressure based on the material properties and thickness, ensuring a more uniform cut.

Working with Complex Part Designs

Complex part designs, such as those with tight radii, detailed corners, or intricate patterns, demand a high level of precision, which can be harder to achieve when cutting through multiple layers of materials.

- Material Behavior: Different materials in a stack respond differently to the abrasive waterjet cutting method. Softer materials may deform under the water stream, while harder materials may require slower cutting speeds. Balancing these variations while maintaining the integrity of a complex design can be tricky.

Solution: One way to manage intricate cuts is by adjusting the cutting speed and water pressure depending on the material type and design. For delicate parts, reducing the speed can enhance control and precision, preventing material warping or chipping. Additionally, dynamic waterjet systems can help to handle intricate designs by automatically adjusting the nozzle angle and speed based on the design’s complexity. - Avoiding Kerf and Tapering: Intricate cuts are more prone to tapering and kerf width issues, where the cut is wider at the top and narrows toward the bottom of the stack. This discrepancy can distort the final design and make the parts unusable.

Solution: Using smaller nozzles and slower cutting speeds can help in reducing tapering and ensuring a more uniform kerf. This results in sharper, more precise cuts that better match the intended design. If tapering continues to be a problem, utilizing taper compensation software can help adjust the cut path dynamically, improving the final result for complex part designs.

Achieving Stack Alignment During Cutting

Misaligned stacks can lead to inaccuracies, such as uneven cuts across different layers, wasted material, and defects in the final parts. Achieving precise alignment is especially important when working with multiple types of materials that may have different thicknesses or densities.

- Material Shifting: One of the primary issues during the cutting process is the shifting of materials within the stack. This movement can occur due to insufficient clamping or improper stacking techniques, resulting in uneven cuts and poor material utilization. To prevent material movement, use appropriate fixturing and clamps that secure the materials firmly in place without causing damage. A well-secured stack ensures that all layers are cut simultaneously and accurately, reducing errors caused by shifting.

- Stack Height Considerations: The height of the stack itself can also present alignment issues. Taller stacks are more likely to experience tapering and alignment problems, especially if the materials are not perfectly flat or have varying thicknesses. Keeping the stack height within the recommended limits for your specific waterjet machine is key. Exceeding the optimal stack height can lead to inconsistencies, as the waterjet may not cut through all layers uniformly. Regularly checking and calibrating the machine for optimal performance can also prevent these issues.

How to Choose the Right Materials for Stacking?

Some materials are better suited for stacking due to their properties and how they interact with waterjet systems. Below are some of the best materials for stacking, along with reasons why they work well in this process:

- Aluminium: Aluminum is a great choice because it is lightweight, has excellent machinability, and cuts smoothly with a waterjet. Its softness allows for high-speed cutting, improving productivity.

- Carbon Fibre: Carbon fiber is ideal for cutting stacked materials because it is lightweight, strong, and delivers clean cuts. It pairs well with waterjets since the lack of heat in the process prevents material damage, which can happen with other cutting methods.

- Stainless Steel: Stainless steel can be stacked effectively due to its durability and corrosion resistance. Waterjet technology cuts through stainless steel layers without generating heat, preserving the material’s integrity.

- Plastics: Many plastics, such as acrylic or polycarbonate, are suitable for stacking. They cut cleanly with waterjets, avoiding the melting or warping that might occur with traditional cutting techniques.

- Composites: Composites like fiberglass are also excellent for stacking. They offer versatility, and waterjet systems handle the precision cutting of these layers well, providing smooth finishes with minimal material wastage.

- Foam: Foam is another material that works well in stacked configurations. It cuts quickly and efficiently, making it perfect for products where fast throughput is necessary.

- Glass: The abrasive waterjet stream precisely penetrates the glass layers without generating excessive vibration, which could otherwise lead to microfractures.

What Safety Measures Should Be Considered When Using Waterjet to Cut Stacked Materials?

Here are seven key safety tips to ensure a safe working environment when cutting stacked materials:

- Wear Proper Protective Gear: Ensure you and your team are equipped with safety goggles, gloves, and ear protection. This protects against particles and noise from the waterjet cutting process.

- Check Machine Integrity: Regularly inspect the waterjet machine and its components, such as pumps, cutting heads, and nozzles, to ensure they are in good condition and functioning properly.

- Secure Materials Firmly: Properly clamp and secure stacked materials to prevent any shifting during the cutting process, which could lead to inaccuracies or accidents.

- Maintain Safe Water Pressure: Set the water pressure according to the material type and thickness to avoid overpressure, which can damage the waterjet machine or cause material failures.

- Use a Safe Distance and Barriers: Always operate the machine from a safe distance, and install protective barriers to separate the operator from the cutting area.

- Monitor the Cutting Process: Continuously monitor the cutting process to detect any issues such as material misalignment or pressure inconsistencies. Immediate corrective action can prevent accidents.

- Ensure Proper Ventilation: Waterjet cutting, especially when working with abrasive materials, can release fine particles. Adequate ventilation and dust collection systems can help reduce inhalation risks

Which Industries Benefit Most from Waterjet Cutting of Stacked Materials?

Waterjet cutting of stacked materials is widely utilized across various industries due to its precision and efficiency. Below are industries that benefit most from this technology and how they use it:

- Aerospace: Waterjet systems cut stacked composite materials like carbon fiber and metals with high precision, producing parts for aircraft without causing heat damage, making it ideal for complex aerospace components.

- Automotive: The automotive industry uses waterjet cutting for parts made from metals, plastics, and composites. It allows for fast production and minimal material wastage, boosting efficiency in the manufacturing of body panels and engine components.

- Construction: In construction, waterjet cutting is used to shape stone, glass, and metal sheets, ensuring clean edges for architectural elements and structural components without compromising the material’s strength.

- Manufacturing: Manufacturers of various products, from electronics to household appliances, rely on waterjet cutting for cutting stacked materials efficiently, enabling mass production of components with precise dimensions and minimal scrap.

- Medical Equipment: Waterjet technology is favored in the medical field for cutting intricate parts from stainless steel, titanium, and plastics used in surgical tools and medical devices, ensuring accuracy without heat-induced material changes.

- Energy: The energy sector uses waterjet cutting to shape parts for turbines, pipelines, and other infrastructure. The versatility of waterjets in cutting different materials makes it suitable for producing durable components.

Why Choose Waterjet Over Other Cutting Technologies for Stacked Materials?

When it comes to cutting stacked materials, waterjet cutting stands out as one of the most efficient and versatile methods. There are five key reasons why you might choose a waterjet over other cutting technologies, especially when handling multiple layers of material.

- One of the primary advantages of waterjet cutting is its cold cutting process, which eliminates the risk of heat-induced material distortion. Unlike laser or plasma cutting, waterjets do not generate heat, meaning materials like composites, metals, and plastics retain their original properties. This is especially important when working with temperature-sensitive materials such as carbon fiber or glass, which could otherwise suffer from thermal damage.

- Waterjet technology also offers exceptional material utilization. With a narrow kerf width, the amount of material wasted during cutting is significantly reduced. This allows you to maximize the use of your raw materials, leading to considerable savings over time. When cutting stacked materials, this efficiency translates into faster production and reduced scrap, making it ideal for industries looking to maintain high throughput without compromising on precision.

- Additionally, waterjets provide versatility across a wide range of materials. Whether you’re cutting metals, foam, or composites, a waterjet can handle different material types and thicknesses within a single stack. The abrasive waterjet option is particularly beneficial for tougher materials like stone or ceramics, offering smooth, clean cuts without damaging the edges of the stacked layers.

- Another critical factor is edge quality. Waterjet cutting is known for producing precision cutting with smooth edges, reducing the need for additional finishing processes. This can save time and labor, especially when dealing with complex part geometries or intricate designs.

- Lastly, safety is a strong selling point for waterjet systems. Since the process doesn’t involve heat, there’s a reduced risk of burns or material combustion, creating a safer work environment. Operators are also less exposed to harmful fumes or particulates that other cutting methods might produce, especially when cutting multiple layers of different materials.

Conclusion

When working with stacked materials, waterjet cutting stands out as the ideal choice for achieving superior results. Its versatility in handling various materials makes it a clear leader compared to other cutting methods.

With waterjet technology, you’re not only getting precise, clean cuts, but also maximizing material use by minimizing waste—leading to significant cost and time savings in the production process.

Whether you’re cutting sheets, composites, or thicker materials, a waterjet system ensures high performance and efficiency. By opting for waterjet cutting, you’re enhancing production quality while ensuring a safe and reliable process for stacked materials, making it the smart choice for any project.