Category: Waterjet Technology

How to Choose the Best Abrasive for Waterjet Cutting?

The appropriate abrasive ensures that the waterjet cuts through different materials precisely, affecting not only the quality of the output but also the cost and speed of operations. Simply choosing a cutter without considering its capabilities can lead to...

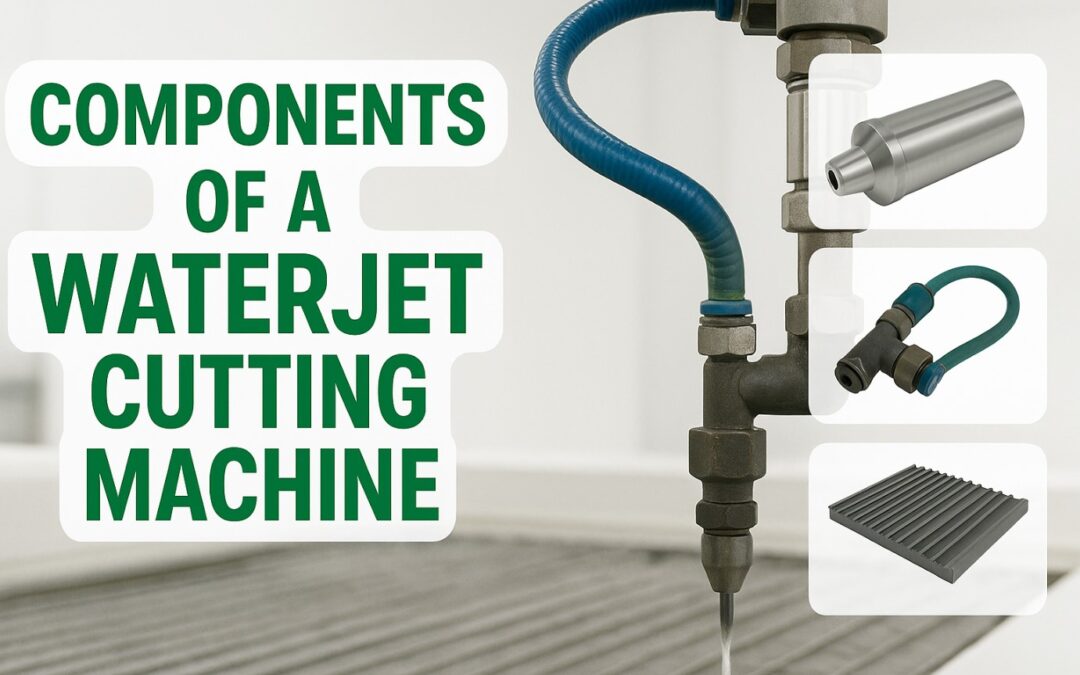

What are The Components of a Water Jet Cutter: 28 Parts and Their Function

To understand a waterjet cutting machine, you need to be familiar with how each individual component comes together to cut various materials including metals. A waterjet machine is quite similar to erosion because of the water force it uses. This might still sound a...

How is Waterjet Controlled?

Understanding waterjet control technology may seem challenging at first, especially if you’re just starting out. However, with practice and a solid understanding of the system, you’ll unlock its immense potential. One of the key elements behind achieving the precision...

Waterjet Cutting Parameters: 21 Types and Optimizing Them

Waterjet cutting is a powerful and versatile method that harnesses high-pressure water to cut through a wide range of materials with impressive precision. To achieve optimal results, it’s essential to fine-tune several key parameters, such as nozzle diameter and...

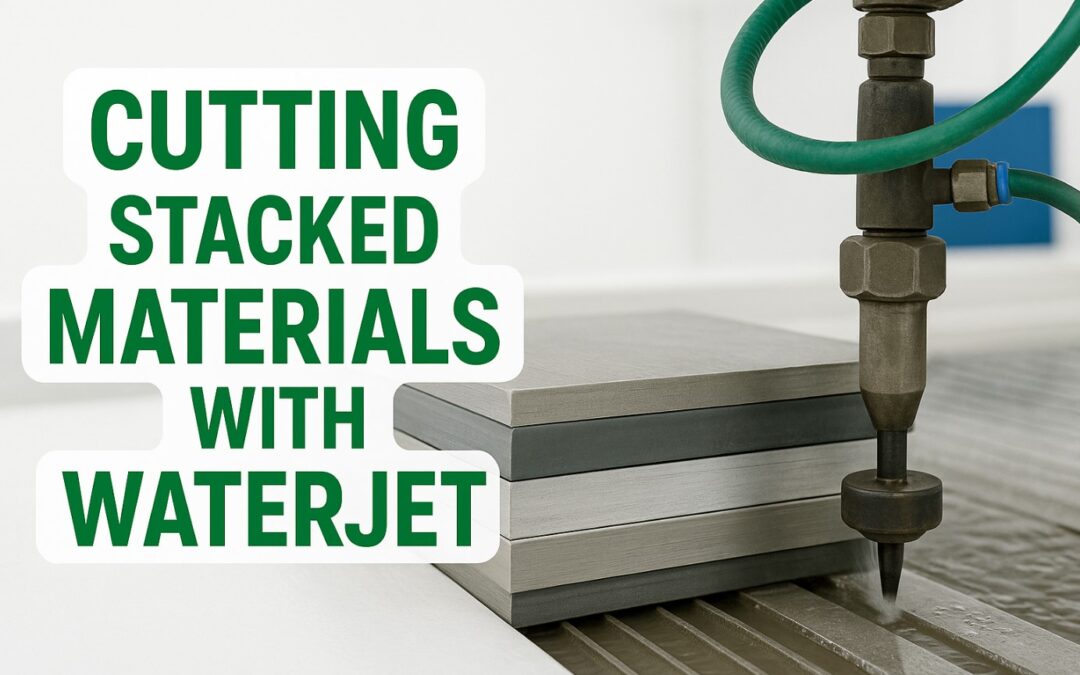

Cutting Stacked Materials with Waterjet Technology

When it comes to cutting multiple layers of different materials, using a technology that streamlines the process is key to improving efficiency. Instead of cutting each layer individually, why not cut them all at once with precision? This is where waterjet technology...

How to Choose the Right Cutting Technology for Your Business

Choosing the right cutting technology is a critical decision for any manufacturer, whether you’re working with metals, plastics, or specialized materials. The cutting method you select can dramatically affect your production speed, cost, and the overall quality...

Waterjet Cutting Vinyl

Waterjet cutting is quickly becoming a popular method for cutting through different materials with unmatched precision, but how well does it cut through vinyl? Applying heat to vinyl is a fast way to compromise its quality and luckily with waterjet technology, such...

What Garnet Sand is Used for Waterjet Cutting?

At the heart of the waterjet cutting technology lies the garnet, a natural mineral known for its hardness and durability, making it the abrasive of choice for waterjet cutting applications. This article will delve into the mechanics of waterjet cutting and explore why...

What is the Importance of Water Quality in Waterjet Cutting?

The linchpin to maximize waterjet cutting performance and longevity might surprise you: it’s the quality of water used in the process. In the article below, we will discuss how important water quality is in waterjet cutting, ensuring operational excellence, and...

Waterjet Cutting Problems: All Issues and Solutions

Diving into the world of advanced manufacturing, waterjet cutting emerges as a pivotal technology. This cutting-edge method, celebrated for its precision and versatility, isn’t without its hurdles. Today, we’re dissecting the common issues that shadow...