Cutting paper might seem like an easy job. However, when we consider the requirements of cutting paper on an industrial scale, like in paper mills, the requirements change significantly.

The strength of paper increases when hundreds of stacked sheets are in a paper machine for cutting. Additionally, some types, such as packaging grades of paper, are tougher than simple writing paper.

Therefore, a specialist paper-cutting machine is needed for precisely cutting multiple sheets or thick bundles of paper. Water jet cutting has become the go-to choice for this purpose. This article will discuss the applications of a water jet to cut paper, the benefits, and tips to improve the cut quality.

Can You Cut Paper With a Water Jet Cutter?

Yes, it is possible to cut paper with a waterjet cutter. In fact, when it comes to cutting paper-based materials, water jet cutting is often better than traditional cutting methods. This is because water jet cutting is not limited by the thickness of the paper. The technology also has several other benefits.

Some people might be skeptical, thinking that water jet cutting is a wet process and will damage the paper during cutting. However, using waterjet cutting technology to cut paper-based materials is very different from using a water jet to cut stone, metals, or other materials. When cutting paper, the thickness of the water stream is less than that of human hair. Therefore, the water jet can perform paper cutting by removing only the material at the cut location without damaging the rest of the paper. This process is called slitting.

What are the Types of Paper That Waterjet Can Cut?

Water jet cutting works for any type of paper, including:

- Copier Paper

- Glass Coated Paper

- Bond Paper

- Acid-free Paper

- Lining Paper

- Artist’s Paper

- Cardstock Paper

- Matt coated Paper

- Heavyweight Paper

- Standard Letterhead Paper

- Recycled Paper

- Protective Poly Coating Paper

- Silk Coated Paper

- Uncoated Paper

- Watermarked Paper

- Newsprint

- Wallpapers

Can You Waterjet Cardboard?

Yes, water jet cutting even works for the thickest paper-based materials, such as cardboard. In fact, multiple layers of cardboard can be stacked on top of each other and cut with a water jet.

What are the Benefits of Using a Water Jet to Cut Paper?

There are many advantages of using a water jet to cut paper. Some of these advantages are:

No Heat-Affected Zones

Heat-affected zones are a common drawback of most cutting methods. However, waterjet cutting is a cold-cutting process, so there are no heat-affected zones. This is particularly beneficial in the paper manufacturing industry, where heat-affected zones can significantly change the appearance of the material or even ruin it entirely. Waterjet cutting preserves the aesthetic appearance of paper as well as its integrity.

Efficiency and Cost-Effectiveness

As mentioned earlier, multiple stacks of paper can be cut simultaneously with a waterjet cutter. Due to this feature, water jet cutting is a highly efficient and cost-effective solution. Additionally, all the edges of all the paper layers are consistent.

Highly Accurate Cutting

Water jet cutting is a very accurate process that uses an ultra-thin waterjet stream and highly controllable cutting heads. The high accuracy of the cutting heads is a key factor for material such as paper because, usually, it will not go through any secondary processing steps. The best cutting nozzles feature a synthetic diamond ring orifice for optimal precision.

Complex and Intricate Designs

Water jet cutting can do much more than making simple incisions on paper. It is possible to create 3D cuts on paper sheets using a multi-axis water jet cutter. These complex designs are helpful for applications like wallpaper where beautiful aesthetics are required.

No Paper Dust

When paper slitting, traditional mechanical trimmers create a lot of torn flying paper pieces and airborne dust. However, in water jet cutting, the paper debris is washed away into the collecting drainage system with the water stream, making a virtually dust-free cutting environment.

Wrinkle-free cutting

Waterjet cutting paper avoids folded paper unevenly wrapping on a spool. This frequently occurs with traditional blade-based cutting methods. But a water jet creates a smooth, virtually wrinkle-free cut edge.

Applications of Waterjet Cutting Paper

There are many areas in which waterjet cutting is used to produce paper products apart from large-scale paper manufacturers. These applications consist of the following:

- Book Covers: Water jet cutting works for any type of book cover, whether paperback or hardcover. Waterjet-cut covers have a very smooth edge that is not possible by other alternatives.

- Business Cards: Business cards are mass-produced by the thousands. With a water jet cutting unit, thousands of business cards can be cut simultaneously within seconds by various sheets of materials on top of one another. The cards produced have consistent edges on a micro-scale.

- Greeting Cards: The primary consideration while cutting greeting cards is to preserve the aesthetic appeal – with no edge defects. This is best done with a cold-cutting process using a water jet.

- Paper Bags: Waterjet cutting is the cheapest and most straightforward method to cut industrial packing paper for bags or other types of paper-based packaging.

- Magnetic Cards: Magnetic cards are made of special durable paper (or plastic). These cards don’t cut well with ordinary mechanical cutters. However, cutting them is a piece of cake with a water jet system.

- Copier Paper: This requires cutting large reams of paper. Ordinary methods are either too slow or create mechanical stresses that can deform the sheet edges. A water jet cutting system eliminates these problems in ream paper cutting.

- Food Industry: Waterjet cutting machines find extensive applications in the food industry. They cut food service paper, primary and secondary packaging material such as protective poly coating paper, and even tertiary cardboard packaging. Water jet cutting is a hygienic method as it doesn’t require physical contact of the cutting tool with the material during cutting.

Tips For Cutting Paper With a Water Jet Paper Cutter

Here are some professional tips for better cut quality and efficiency when using water jet technologies for paper cutting.

- An abrasive water jet system is ideal for cutting metals and other hard materials. However, there is no need for abrasive water jets for paper cutting. A pure water jet produces better quality paper cutting at a significantly lower cost. A pure waterjet stream is the best choice for paper-thin materials, unlike abrasive waterjet cutting, which works best for stone, metals, and plastics.

- Try stacking materials depending on their product dimensions. For instance, stacking works well with products like business cards, copier reams, legal paper, etc. However, stacking has limitations when every individual piece has customized dimensions.

- The high-pressure water used in the cutting process can be recycled. Use a mesh to separate the dust from the water before recycling so that it does not clog the systems.

Factors to Consider When Choosing a Water Jet Paper Cutter

When deciding between different water jet systems to cut paper, consider the following factors:

Pump Size

Water jet technology works by using ultra-high pressure to cut through materials. However, paper is not as hard as materials like stone and metals. Therefore, a low to medium-pressure pump might suffice if your only requirement is to cut paper.

Budget

The price range of water jet systems is vast. A high-end waterjet stream will come with multi-axis functionality capable of cutting complex designs. But a less advanced machine might be suitable if you only need a water jet edge trimmer for cutting paper.

Manufacturer

When it comes to water jet systems, the brand matters. Brands such as Techni Waterjet have a reputation for providing superior build quality. Their products come with a warranty that reflects this. On the other hand, a local, non-branded water jet might break the next day, and there will be no one to replace or fix it.

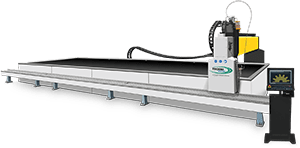

Recommended Waterjet Machines

You get the most value for money and the best features with Techni Waterjet’s water jet nozzle-mounted cutters. These can cut paper-thin materials and several inches of thick steel, aluminium, titanium, wood, and even the hardest alloys.

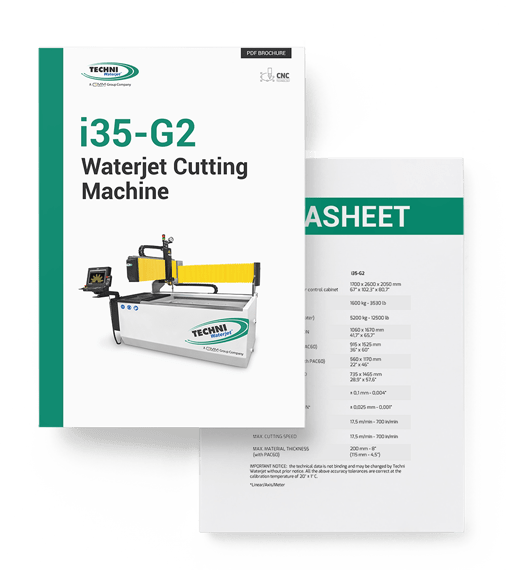

i35-G2

Waterjet Cutting

Machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | 0.1mm - 0.004" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

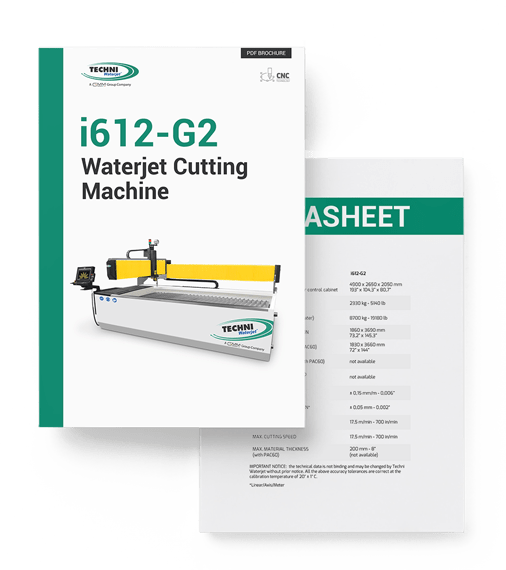

i612-G2

Waterjet Cutting

Machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

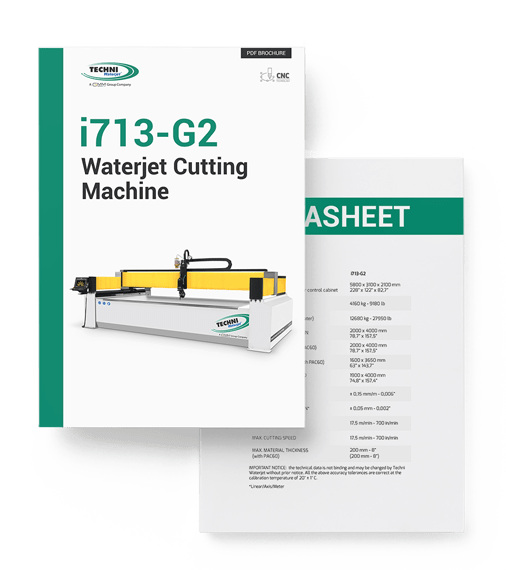

i713-G2

Waterjet Cutting

Machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

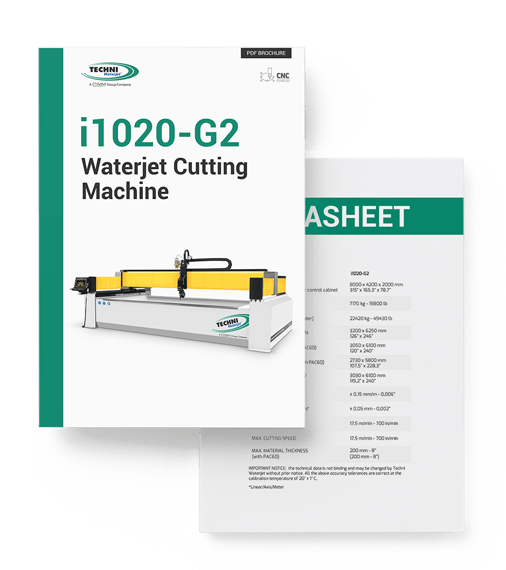

i1020-G2

Waterjet Cutting

Machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i510-G2

Waterjet Cutting

Machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.12 mm - 0.005" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i613-G2

Waterjet Cutting

Machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 130mm - 5" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i815-G2

Waterjet Cutting

Machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i1033-G2

Waterjet Cutting

Machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ± 0.1 mm - 0.004” |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

Is a Waterjet the Best Solution for Cutting Paper?

Considering the benefits of a water jet tail cutter, it is the best option for paper cutting. In fact, a waterjet cutter is the first choice of professionals for paper and many other materials. Therefore, a water jet machine is ideal for many versatile uses when it is not busy processing your paper-cutting requirements.

Conclusion

Water jet cutting technologies have replaced traditional mechanical tail cutters due to their accuracy, cut quality, and many other benefits. A water jet cutting machine is the perfect solution if you want to cut almost all paper grades with fewer sheet breaks.

For more information, browse the vast catalog of Techni Waterjet CNC Cutters and find out why they are the industry’s leading machines for waterjet cutting paper.