Various plastic materials have become commonly used in the design of every kind of product, including electronics, furniture, tool casings, appliances, and packaging.

With hundreds of plastics with different physical properties, manufacturers require cutting methods that work effectively on all plastic materials. Waterjet-cutting plastic has emerged as the clear winner in this regard.

This article explores waterjet cutting plastic, its benefits, applications, and some tips that can improve the waterjet cutting process.

Can You Cut Plastic With a Water Jet Cutter?

Yes, cutting plastic with a water jet cutting machine is possible. In fact, water jet technology is one of the best methods for cutting plastic components in any shape.

What are the Plastics That a Waterjet Can Cut?

Water jet cutting applies to a lot of different plastics, such as:

Polyvinyl Chloride (PVC)

Polycarbonate (PC)

Polypropylene (PP)

Low-Density Polyethylene (LDPE)

High-Density Polyethylene (HDPE)

Ultra High Molecular Weight Polyethylene (UHMW)

Polyoxymethylene (POM or Acetal)

Polyethylene Terephthalate (PET)

Polyamides (Nylon)

Polystyrene (PS or Styrofoam)

Acrylonitrile Butadiene Styrene (ABS)

Carbon Fibre (CF)

Polytetrafluoroethylene (PTFE or Teflon)

Polysiloxane (Silicone)

Garolite (G10-FR4)

Poly Paraphenylene Terephthalamide (Kevlar)

What are the Benefits of Using a Water Jet to Cut Plastics?

Many advantages make waterjet cutting the best method for cutting plastic. Here are some of the advantages:

No Melting, Heat, Dust, or Fumes

Water jet cutting is a cold-cutting process, so it doesn’t affect the material being cut and prevents heat-related distortion. Using traditional cutting methods on plastics leads to overheating of the plastic and can result in melting. It can also cause the emission of toxic fumes in the workplace environment.

Stack up to 8 inches

Water jet cutting can cut plastics up to 8 inches thick with ease. If your project uses thinner plastics, you can stack multiple layers of softer materials (including rubber and foam) on top of each other and cut them simultaneously in a single pass with a water jet. This process is called stacking.

Efficient and Cost-Effective

Since most manufacturers cut multiple plastic sheets with a water jet, productivity increases exponentially, making waterjet cutting plastic one of the most efficient methods. This high efficiency also makes waterjet cutting plastic the most cost-effective solution.

Highly Accurate Cutting

Waterjet cutting plastic uses a thin stream of water with a highly controllable cutting head. This leads to precise cuts to tight tolerances. The waterjet process also helps to minimize kerf width and produce parts with very high accuracy.

Minimum Material Wastage

Precise cutting means less raw material wastage due to defects and rejections. Additionally, there is minimal removal of material and no wastage due to any adverse heat-affected zone. This makes the process very favorable for manufacturers who want to optimize their raw materials.

Smooth Edges without Burrs/burn marks

Cutting plastic materials using blades or other conventional techniques leads to unwanted, serrated edges. However, abrasive waterjet cutting produces smooth edges without heat marks on the surface.

Applications of Waterjet Technology for Plastic Cutting

Many manufacturers use waterjet cutting services. Some applications and use cases are listed below.

Toys: Toy production uses plastic materials extensively. High-speed cutting of these raw materials is done with a waterjet cutter, reducing the cost of the final product while ensuring quality.

Bottles: Waterjet cutting is also used for cutting high stacks of plastic raw materials for making water and oil bottles. Since waterjet cutting doesn’t involve direct contact of the cutting nozzle with the plastic, it is a hygienic process. Even bottle caps are made using a water jet.

Packaging Trays: Food packaging trays are an everyday item. A waterjet cutter provides a hygienic way to make these trays.

Signage: Aesthetically appealing 3D plastic signs and logos can be made for commercial shops and businesses using waterjet cutting technology.

Computer Hardware Casings: The casing and peripheral bodies require a high-quality cutting process like a waterjet to produce a smooth finish and 3D cut shapes.

Furniture: The requirements to manufacture plastic furniture like tables and chairs demand a machine capable of handling large-size furniture items. Waterjet cutting is a scalable solution in such cases.

Miscellaneous: Many other sectors rely on waterjet cutting of plastic. Other products made using this method are plastic soap containers, pipes, first-aid blankets, and protective shells.

Tips for Cutting Plastic With a Waterjet

Here are some tips to improve the quality and efficiency of cutting plastic with a waterjet.

Waterjet cutting is a green process since the water used in the process can be recycled. The system incorporates a mesh that collects the removed plastic particles and lets the clear water pass through. Make sure to clean the mesh regularly to deliver optimal results.

The stacking method increases the efficiency and productivity of cutting plastic materials. However, stacking only works well when the pieces have consistent cutting requirements with identical dimensions.

Waterjet cutters easily cut through 8 to 12 inches of plastic material. Many machines have the ability to handle even thicker materials, but the cutting process takes longer. When stacking layers of plastic materials, refer to the manufacturers’ guidelines about the maximum thickness for the machine.

Soft materials like plastic don’t require abrasive waterjet cutting. Pure waterjet works well for cutting plastic, with a water pressure of about 50,000 psi. Additionally, using pure waterjet cutting saves money by eliminating expenditure on abrasives.

Like other manufacturing processes, cutting plastic with a water jet generates significant noise during operation. However, submerged waterjet cutting helps eliminate some of the noise.

How to Choose a Water Jet Plastic Cutter?

When choosing a water jet cutter to cut plastics, here are some things to consider:

Budget

Waterjet cutters can be cheap or expensive, depending on what you need. The price is also influenced by the number of cutting axes, speeds, build quality, and features. It’s best to fix your ideal budget before shopping for a waterjet cutter.

Warranty

Good quality waterjet cutters come with a warranty for the machine and its parts. It is always a good idea to check the integrity of the supplying company since you are making a significant investment.

Pump Size

Choosing the ideal pump size is vital. If you only need to cut plastics and not harder materials like tool steel or stone, a medium-sized pump of around 50,000 psi will do the job. It is better to choose a high-pressure pump if you need to cut hard materials like metals and alloys.

Underwater Cutting

Underwater cutting is a feature worth getting in your waterjet cutter, even if it costs a bit extra. Underwater cutting eliminates noise and any dust or debris in the workspace.

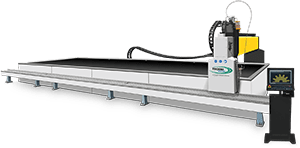

Recommended Waterjet Machine

Based on the considerations mentioned above and many more, Techni Waterjet Intec-G2 CNC cutters are the best option in any price range.

Our dynamic waterjet machines come with industry-leading build quality, innovative design, and an extended warranty to reflect the high standard of quality.

Besides feature-loaded cutting options and flexible tooling, you get complimentary software to control the machine at the click of a button. The software is preloaded with common cutting shapes that make the process simpler. For regular applications, you can load simple/complex cutting shapes into the machine and save them for future use.

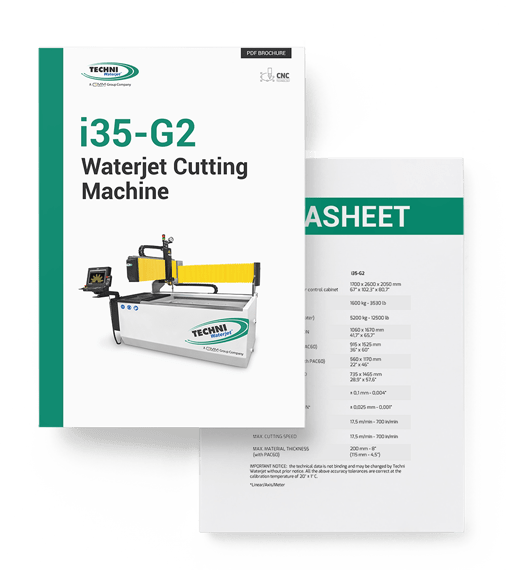

i35-G2

Waterjet Cutting

Machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | 0.1mm - 0.004" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

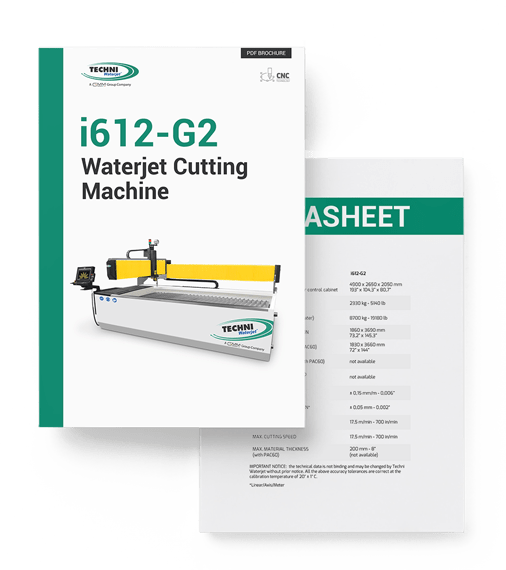

i612-G2

Waterjet Cutting

Machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

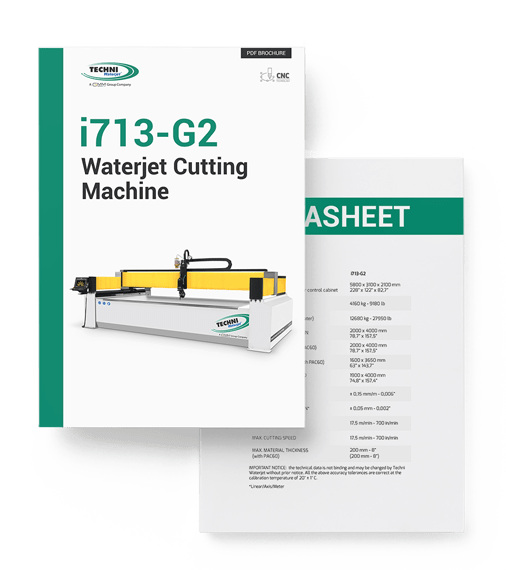

i713-G2

Waterjet Cutting

Machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

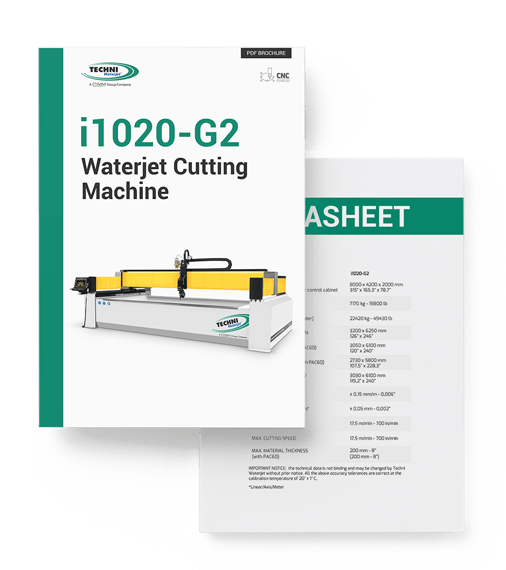

i1020-G2

Waterjet Cutting

Machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

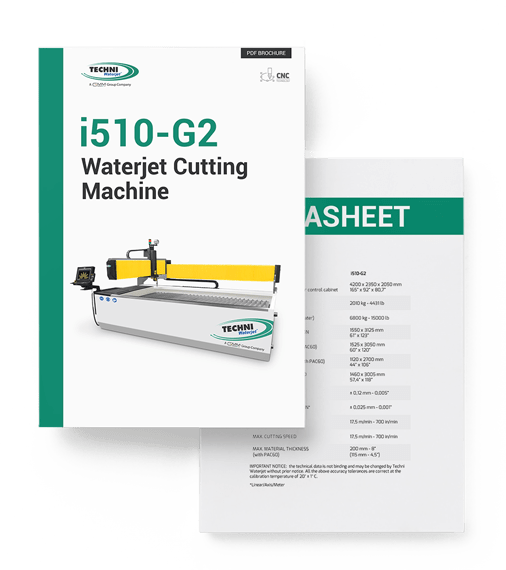

i510-G2

Waterjet Cutting

Machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.12 mm - 0.005" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

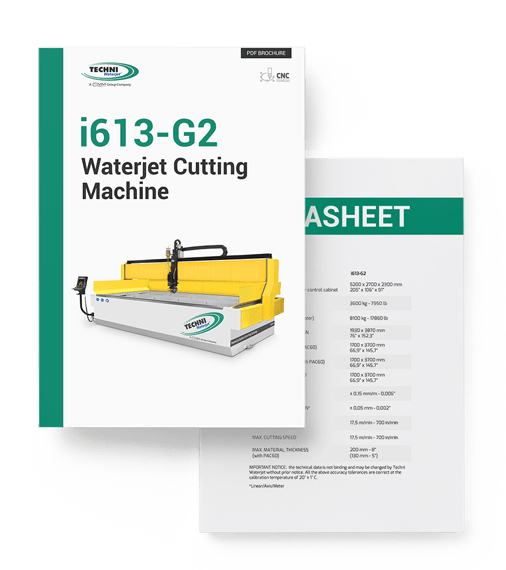

i613-G2

Waterjet Cutting

Machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 130mm - 5" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

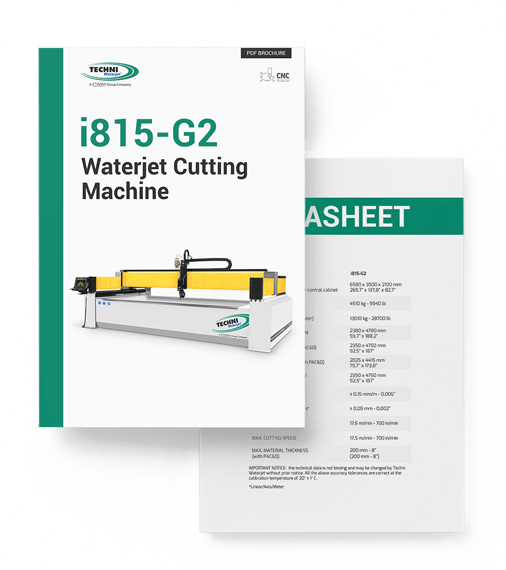

i815-G2

Waterjet Cutting

Machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

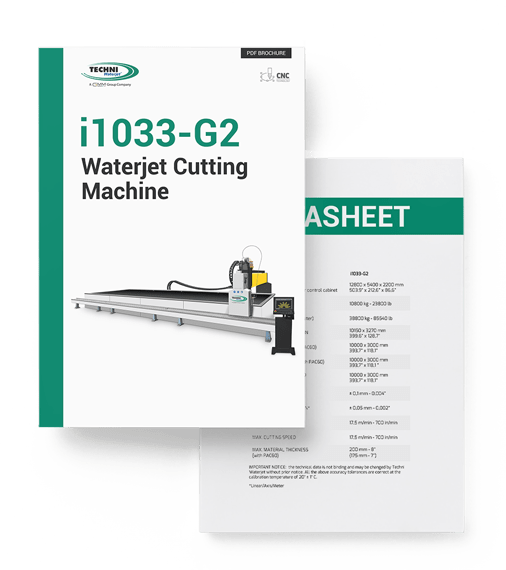

i1033-G2

Waterjet Cutting

Machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ± 0.1 mm - 0.004” |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

Is a Waterjet the Best Solution For Cutting Plastic?

Yes, waterjet cutting plastics is absolutely the best method. Although many plastic cutting options are available (such as laser cutting), other methods create heat and burrs that cause distortion, especially in the heat-affected zone.

However, waterjet cutting has none of these disadvantages and doesn’t compromise cut accuracy or quality. Therefore, the waterjet cutting process has become the go-to choice for professionals.

Conclusion

You encounter things every day that are made using plastic waterjet cutting. Waterjet cutting plastic outperforms all other alternatives due to its many benefits without any downsides.

Are you considering using waterjet cutting technology in your workspace? You should! It works just as well for complex shapes as for simple ones. It’s fast, efficient, and cost-effective. For more information and product quotes, browse through Techni Waterjet’s catalog or get in touch to talk with an expert.