Waterjet cutters are gaining popularity due to the advantages they provide over other industrial cutting processes. This is why more and more professionals are looking forward to understanding the technology behind the process. Water jet Kerf is something we stumble on quite often in regards to waterjet cutting process. If you want to create accurate parts with any cutting process, the Kerf of the process is something you have to account for. This article will discuss in detail all the things you should know about Water jet Kerf. After reading this information, you will be able to calculate the waterjet kerf yourself. You will also know about waterjet kerf versus the kerf for other cutting processes.

What is kerf in waterjet cutting?

Kerf refers to the amount of material that is removed from the workpiece during waterjet stream cutting. To understand this better, think of a carpenter working on a wooden piece with a saw. When cutting the piece, some of the wood is removed from the point of impact and turned into sawdust. This is the kerf for the saw cutting process. Similar is the case in waterjet cutting. When high-pressure water hits a workpiece, the material of the workpiece is disintegrated at the point of impact, and the amount of material removed is proportional to the thickness of the water stream.

Why is a kerf important?

Kerf is an important factor to consider when we are talking about any cutting process. If the kerf is higher than acceptable, there will be a lot of material going to waste.

As you can imagine, the smaller the Kerf width, the more efficient the cutting process.

Additionally, after cutting, the dimensions of the final piece might be different than what is intended. This can be a deal-breaker for applications that are sensitive to minute changes in dimensions. Therefore, considering the kerf is important for not only waterjet cutting but also any other cutting technology as well. When creating high accuracy parts isn’t a necessity and an inch here and there won’t matter, the kerf is not something you need to care about. You can even use guesswork to compensate for the kerf for low precision requirements. However, when it comes to precision manufacturing, calculating the Kerf is indispensable.

What is the average kerf width in waterjet cutting?

In general, the kerf in waterjet cutting turns out to be somewhere between 0.03 inches to 0.04 inches. This figure is significantly smaller than other cutting alternatives, mainly because waterjet cutting utilizes a very thin stream of pressurized water.

How to calculate kerf for your water jet machine?

Calculating the kerf for your waterjet machine is a very easy process:

- To start with, all you need is a small sample piece of a known dimension, such as a one-inch square steel piece.

- Them, cut this piece in half with your water jet cutter and measure the length of the final pieces added together. They will add up to something less than one inch, and the difference will be your kerf value.

For instance, if the length of the resultant pieces is 0.49 inches each, the total length becomes 0.98 inches. Therefore, the kerf value becomes 0.02 inches. Once you have calculated the kerf, you can adjust the length of the workpiece to create the desired final piece. If you want two pieces of one-inch length each, add 0.02 inches on the initial workpiece to compensate for the kerf. The good thing is that most waterjet controllers can compensate for the Kerf width automatically!

**Important Tip: Due to the Kerf you will also need to take into account the tool offset. The tool offset is the shift in the position of the cutter to create the cut in the intended place, taking into account the kerf of the cutting process.

Mathematical Expression

Mathematically, suppose the length of the initial workpiece is X. After cutting, the length of the final pieces is Y and Z. The Kerf (K) will be

K= X- (Y+Z)

I.e. the kerf is the initial length minus the total final length. Since the total final length is always less than the initial length as some material is wasted away in cutting, the Kerf will always be a positive value.

What factors influence kerf in waterjet cutting?

Several factors influence the kerf in waterjet cutting. These factors include:

- Workpiece Material – The material that you are cutting will always influence the kerf since different materials have different mechanical strengths and properties. When cutting new material with your waterjet cutter, you should calculate the kerf for that material beforehand with the process mentioned in the previous section.

- Nozzle Head – The nozzle head determines the width of the water jet that will create the cutting action. If you are using a thin nozzle, the kerf will be lower. Additionally, a worn-out nozzle head will lead to a higher kerf than a brand new nozzle.

- Cut Design – When cutting in a straight line, the kerf is smaller as compared to cutting corners or creating circular cuts. This is because the machine slows down the cutting speed at corners, leading to a higher kerf value there. In straight cuts, the cutting speed is high leading to lower kerf value.

- Abrasive – Some people believe that by using pure waterjet cutting they can lower the Kerf value than abrasive waterjet cutting. However, abrasive waterjet cutting has a lower kerf than pure waterjet cutting since the former can provide more force with a thinner stream. Additionally, higher-quality abrasives provide lower kerf value.

- Waterjet Pressure – By using higher water pressure, you can narrow down the thickness of the water stream required to create the cutting action. This will result in a smaller kerf value.

How does waterjet kerf compare to other cutting methods?

Water jet cutting is a mechanical cutting technology as opposed to thermal cutting methods such as laser cutting, plasma cutting, EDM cutting, and Oxy-fuel cutting. The thermal cutting methods rely on creating the cutting action by melting the material at the point of impact. The melting takes place not only on the point of impact but also on the adjacent areas due to the thermal conductivity of the material. However, since waterjet cutting is a cold cutting process, the kerf is limited only to the point of impact. This means that the kerf involved in water jet cutting will always be lower than these other methods. Here is a table of typical kerf width for various cutting processes:

Kerf Width (inches)

- Waterjet Cutting ~0.035

- Plasma Cutting ~0.150

- Oxy-fuel Cutting ~0.045

- Laser Cutting ~0.030

Conclusion

A waterjet cutter is an optimal choice for any manufacturer who wants to make precise cuts while preserving the integrity of the material. However, to ensure precision, you will always need to take the waterjet cutting kerf into account. By compensating for the Kerf, you can make the final pieces as per the intended dimensions.

One thing to remember is that some Kerf is involved regardless of which cutting method you choose. The advantage of waterjet cutting is that it involves a Kerf lower than other cutting processes. I

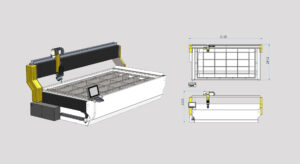

If you are considering waterjet cutters for your business, it is a good idea to browse our range of CNC water jet cutters. TechniWaterjet has very reliable, professional-grade waterjet cutters that can handle whatever you throw at them.