What Should You

Consider Before Buying a Waterjet Cutting Machine?

Things to consider are:

COST

material

size

features

WHAT MATERIALS

With many other alternative cutting methods, the types of materials that are needing to be cut is the first point that you should focus on. However, because Waterjets can cut almost any material, the material to be cut is not so important. While almost any waterjet can cut almost any material, some machines are still better suited to certain materials. For example, when cutting steel you will typically choose a more powerful and a more accurate waterjet, so that you can cut it faster with more precision, compared to if you were cutting glass. Before we move on, let’s have a look at the range of materials that you can cut on a waterjet. Waterjets can quickly and accurately cut soft materials such as; rubber, foam, cork, and other gasket material with a pure water stream.

When cutting harder materials an abrasive is added into the stream. You can then cut almost any material, over a very wide range of thicknesses, for example;

VIRTUALLY ALL METALS

NON-TEMPERED GLASS

Composites

Laminates

Stone

Most ceramics

how many

what size of

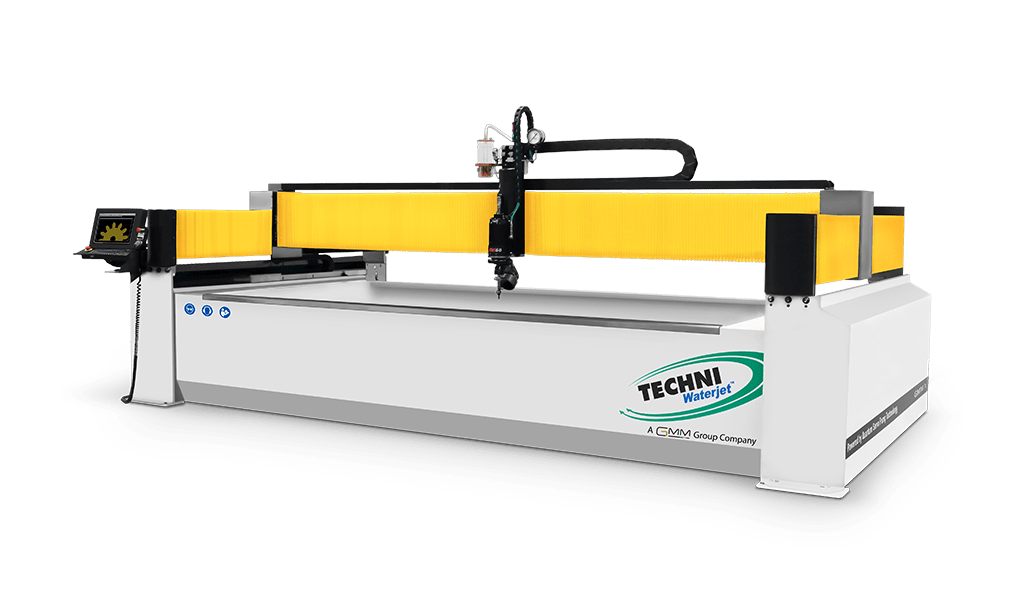

Our waterjet machines come in a range of sizes to help suit all types of businesses and applications. These are things such as material types, part sizes, part accuracy, production runs, & workshop size and staff availability. If you have the room, we always consider pointing our customers in the direction of owning larger machines with bigger bed sizes, so that they are not met with the limitations in the future if they ever have the need to cut parts that are bigger in size. We are also aware that space limitations can be a major factor to consider, so we also have smaller machines available.

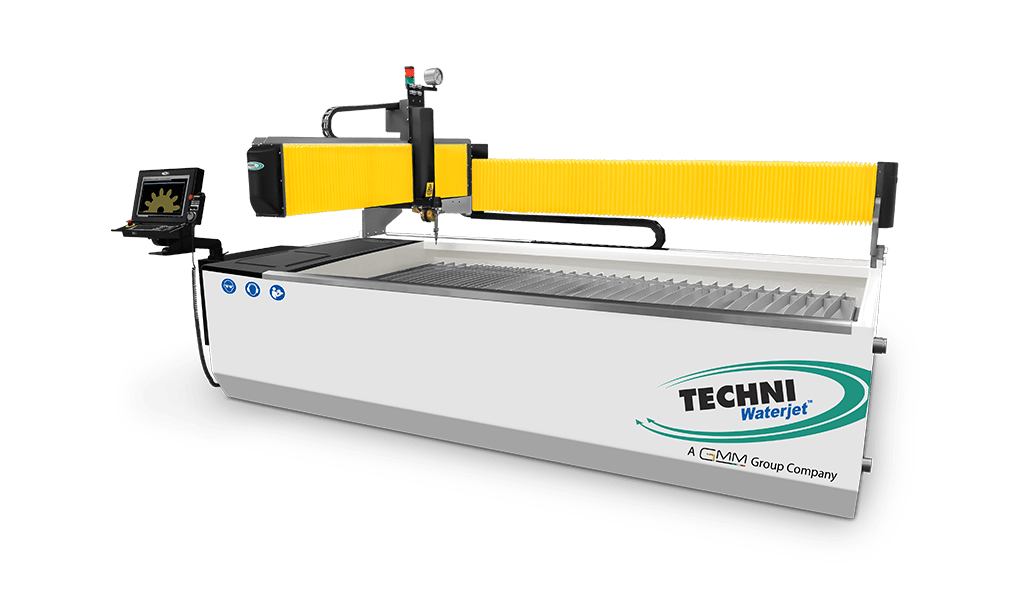

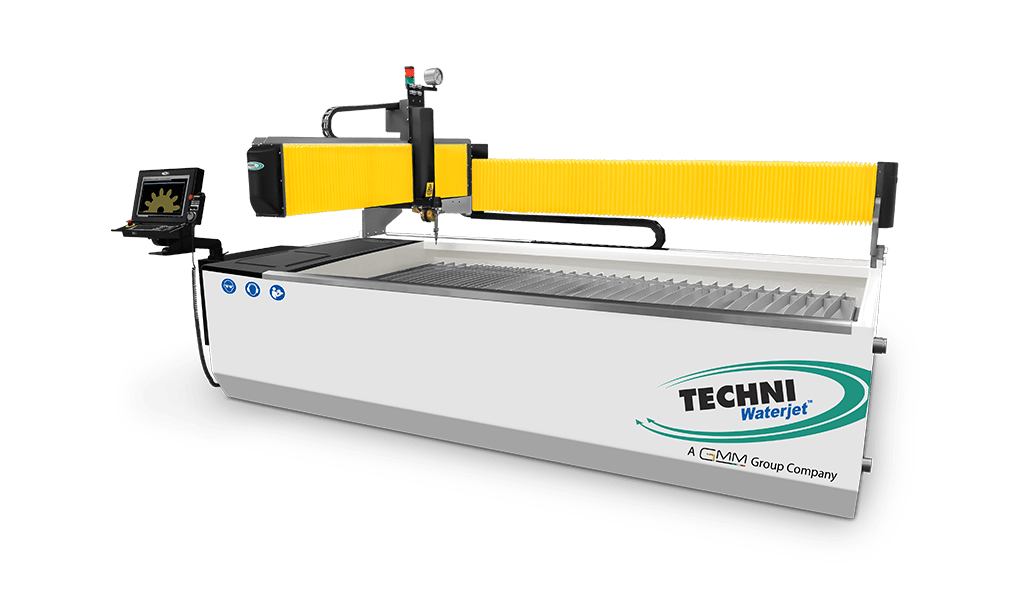

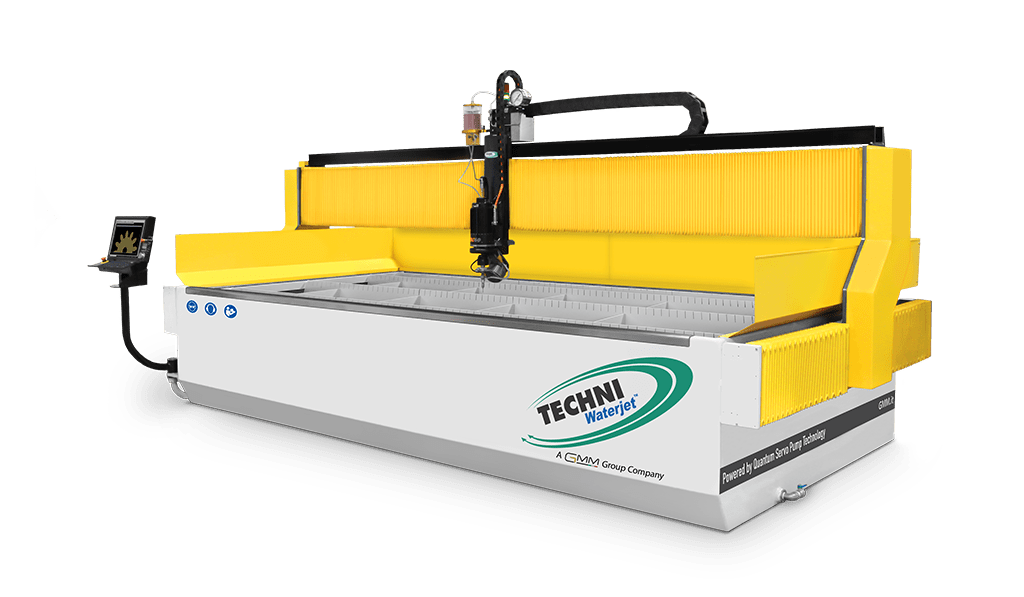

Our smallest machine, known as the i35–G2, is sized at 1770L x 2600W x 2050H mm and is great for smaller workshops and small precision parts and prototype parts. Whereas our largest machine being i1033–G2 which is sized at 12800L x 5400W x 2200H mm is great for bigger workshops, large parts and high production applications.

i35–G2

Upgrade Option – Linear Scale Feedback

Accuracy ± 0.05mm/m – 0.002″

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i35-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 1700 x 2600 x 2050 mm 5' 5" x 8' 6" x 6' 6" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.1 mm/m ± 0.004" |

| MACHINE WEIGHT without water | 1600 kg 3530 lb | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.025 mm ± 0.001" |

| CUTTING TABLE SIZE | 1060 x 1670 mm 3' 6" x 5' 6" | MAX CUTTING SPEED | 17.5 m/min 700 in/min |

| CUTTING AREA* | 915 x 1525 mm 3' x 5' | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i510–G2

Upgrade Option – Linear Scale Feedback

Accuracy ± 0.05mm/m – 0.002″

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i510-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 4200 x 2350 x 2050 mm 14' x 7' 8" x 6' 8" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0,12 mm/m ± 0,005" |

| MACHINE WEIGHT without water | 2010 kg 4440 lb | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.025 mm ± 0.001" |

| CUTTING TABLE SIZE | 1550 x 3125 mm 5' 1" x 10' 3" | MAX CUTTING SPEED | 17.5 m/min - 700 in/min |

| CUTTING AREA* | 1525 x 3050 mm 5' x 10' | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i612–G2

Upgrade Option – Linear Scale Feedback

Accuracy ± 0.05mm/m – 0.002″

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i612-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 4900 x 2650 x 2050 mm 16' x 8' 6" x 6'8" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.15 mm ± 0.006" |

| MACHINE WEIGHT without water | 2330 kg 5140 lb | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.05 mm ± 0.002" |

| CUTTING TABLE SIZE | 1860 x 3690 mm 6'1" x 12'1" | MAX CUTTING SPEED | 17.5 m/min 700 in/min |

| CUTTING TABLE AREA* | 1830 x 3660 mm 6' x 12' | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i613–G2

Upgrade Option – Linear Scale Feedback

Accuracy ± 0.05mm/m – 0.002″

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i613-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 5200 x 2700 x 2300 mm 17' x 8' 11" x 7' 6" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.15 mm/m ± 0.006" |

| MACHINE WEIGHT without water | 3600 kg 7950 lbs | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.05 mm ± 0.002" |

| CUTTING TABLE SIZE | 1930 x 3870 mm 6' 4" x 12' 8" | MAX CUTTING SPEED | 17.5 m/min 700 in/min |

| CUTTING AREA* | 1700 x 3700 mm 5' 7" x 12' 2" | MAX MATERIAL THICKNESS** | 130 mm 5" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i713–G2

Accuracy ± 0.05mm/m – 0.002″

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i713-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 5800 x 3100 x 2100 mm 19' x 10' 2" x 6' 10" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.15 mm/m ± 0.006" |

| MACHINE WEIGHT (with tank) without water | 4160 kg 9180 lbs | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.05 mm ± 0.002" |

| CUTTING TABLE SIZE | 2000 (XL 2200) x 4000 mm 6' 6" (XL 7' 2") x 13' 1" | MAX CUTTING SPEED | 17.5 m/min 700 in/min |

| CUTTING AREA* | 2000 x 4000 mm 6' 6" x 13' 1" | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i815–G2

Upgrade Option – Linear Scale Feedback

Accuracy ±0.15 mm - 0.006"

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i815-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 6580 x 3500 x 2100 mm 21' 7" x 11' 6" x 6' 10" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.15 mm/m ± 0.006" |

| MACHINE WEIGHT (with tank) without water | 4510 kg 9940 lbs | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.05 mm ± 0.002" |

| CUTTING TABLE SIZE | 2380 x 4780 mm 7' 9" x 15' 8" | MAX CUTTING SPEED | 17.5 m/min 700 in/min |

| CUTTING AREA* | 2350 x 4750 mm 7' 8" x 15' 7" | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i1020–G2

Upgrade Option – Linear Scale Feedback

Accuracy ± 0.05mm/m – 0.002″

Repeatability ± 0.025mm/m – 0.001″

Specifications

| MODULE i1020-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 8000 x 4200 x 2000 mm 26' 3" x 13' 10" x 6' 6" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.15 mm ± 0.006" |

| MACHINE WEIGHT (with tank) without water | 7170 kg 15800 lbs | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.05 mm ± 0.002" |

| CUTTING TABLE SIZE | 3200 x 6250 mm 10' 6" x 20' 5" | MAX CUTTING SPEED | 17.5 m/min 700 in/min |

| CUTTING AREA* | 3050 x 6100 mm 10' 20' | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

i1033–G2

Linear Scale Feedback standard fitted

Accuracy ± 0.01mm/m – 0.004″

Repeatability ± 0.05mm – 0.002″

Specifications

| MODULE i1033-G2 | |||

| MACHINE SIZE (L x W x H) without high pressure pump or abrasive transfer system | 12800 x 5400 x 2200 mm 41' 12" x 17' 8" x 7' 2" | ACCURACY OF MOTION (Linear/Axis/Meter) | ± 0.01 mm ± 0.004" |

| MACHINE WEIGHT without water | 10800 kg 23800 lb | REPEATABILITY OF MOTION (Linear/Axis/Meter) | ± 0.05 mm ± 0.002" |

| CUTTING TABLE SIZE | 10150 x 3270 mm 33' 3" x 10' 8" | MAX CUTTING SPEED | 10 m/min 400 in/min |

| CUTTING AREA* | 10000 x 3000 mm 32' 9" x 9' 10" | MAX MATERIAL THICKNESS** | 200 mm 8" |

| * Additional options such as the PAC and/or Ezy Load may reduce the Cutting area. See the PAC manual for more details. ** Additional options such as PAC, Ezy Load and/or Skip and Float may reduce the maximum material thickness and travel. See the PAC manual for more details. | |||

What kind of

Our Quantum® pumps are engineered on the basis of eliminating pressure spikes and they are proven to be 60% more efficient than standard hydraulic intensifiers.

You can read more about our Quantum® range of pumps here

What kind of

Waterjet cutting comes with some features that are unique to this type of cutting process. Some of these features make it extremely attractive to workshops when compared to alternative methods of cutting. Here are some of the waterjet cutting benefits to take into consideration before choosing to buy a Waterjet machine.

No Heat

Complex Shapes & Designs

Waterjets make a very narrow cut (waterjet kerf) and have very low cutting forces. This allows part designers to have more freedom when creating intricate parts that are impossible with other cutting methods.

Low Waste Volumes

Ease of Use

What kind of

1

2

What kind of

Waterjet?

A number of factors need to be taken into account when calculating an accurate figure for the operating cost of an abrasive Waterjet cutting machine. These are factors such as; Utility costs (electricity and water), consumables (abrasive material, cutting head parts etc), operator time, programming time and maintenance costs.

A typical Waterjet machine will cost around $15 – $50 per hour to operate when all these factors are considered. Some of these factors are influenced by the speed you want to cut at and the thickness and hardness of the materials being cut.

These costs are minimised in a Techni Waterjet by; using the most efficient pump on the market, making programming quick and simple to minimise the programming time, allowing for lights out operation to minimise operator time, installing an Abrasive Removal System to automatically remove the abrasive from the tank, installing an efficient cutting head which minimises garnet use and maximises cutting speeds, and having a machine which is designed to deal with the very harsh Waterjet environment to minimise maintenance and maximise up time.