introducing the quantum®

The Future in Waterjet

Pumping Technology

Water Jet Pumps

Faster. Quieter. Smarter.

water jet pump

Water Jet Pump Core Technology

Real Efficiency Gains

Up to 60% more efficient than standard hydraulic intensifiers

Lowest Cooling Water Requirement

Up to 75% less cooling water than

standard hydraulic intensifiers

Longest Life Fittings & Tubing

Due to the elimination of ”dead head” pressure spikes

Smallest Carbon Footprint

Up to 50% less sq. ft. than an average hydraulic intensifier and lower

faster. quieter. smarter

quantum®

Pumping Technology

The Techni Waterjet® Quantum® water jet pump is a revolutionary concept in waterjet cutting. It incorporates a servo motor directly enveloping a high load, precision ball screw. The ball screw directly houses the ceramic plungers, which reciprocate back and forth to create the pumping action, in much the same way as hydraulic cylinder works on an intensifier waterjet pump.

The infinite control of the servo motor and precision of the ball screw, enable extremely accurate control over the output pressure and volume of the water displaced and eliminates pressure spikes when deadheading. This infinite control gives an operator the ability to program virtually any pressure and flow rate from zero to full capacity, while only the power displaced at the cutting head.

Most Efficient

Hydraulic Intensifiers

Quietest

Hydraulic Intensifiers

Lowest Costs

Up to 300% increase in HP tubing

and fitting life, due to superior

pressure control

Real Efficiency Gains Means Real Savings

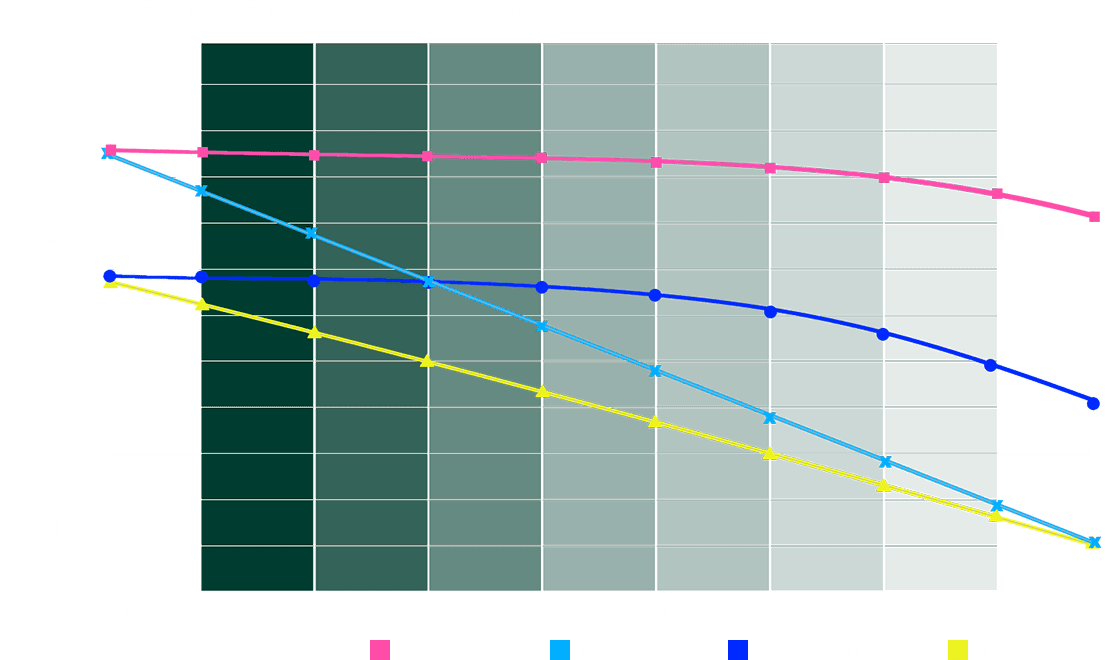

The below graph highlights the increasing efficiency gains achieved with the

Quantum® as duty cycle decreases.

VIEW OUR

QUANTUM® PUMP SERIES

SPEAK TO A QUANTUM PUMP

SPECIALIST TODAY

electric servo pump

Efficient Pump on the Market

This same style actuator is used today in many high-end machine tools and presses replacing inefficient hydraulic systems. Similarly, Quantum® is the first water jet pump manufacturer to utilize “direct servo” technology in an ultrahigh pressure waterjet pump and has developed patented designs to integrate the core technology into the most efficient, reliable and controllable ultra-high pressure (UHP) waterjet cutting pump.

The Best of Both Worlds

Traditional waterjet pumps are categorized into two main types – intensifier pumps and direct drive crankshaft pumps. These two types offer different benefits, but both have considerable limitations.

Intensifier waterjet pumps are capable of delivering higher operating pressures, can support multiple nozzles, and can be “dead-headed” by holding pressure without any water being displaced. While dead-heading is desirable to pause or hold the cutting operation, it results in unwanted pressure spikes of up to 10% of the operating pressure, which is harmful to components and causes failure in high pressure piping and fittings. Intensifier pumps are typically very inefficient, large and noisy.

Direct drive crankshaft pumps are smaller, quieter and more efficient, but cannot dead-head, and must displace the water whenever the motor is on, which is done by dumping the water over a relief valve to drain. As a result, it is not practical to run multiple heads or varying orifices, as the unused water and energy is wasted. Direct drive crankshaft water jet pumps are not suitable for running varying pressures, and are less reliable than intensifier pumps due to their high plunger piston speeds.

The Quantum® takes advantage of all the best features of the two existing technology pumps, while having none of their limitations.

Real Efficiency — Real Savings

The Quantum® is by far the most efficient water jet pump available on the market, delivering real efficiency gains and real savings. Direct drive crankshaft waterjet pumps have traditionally been marketed for their efficiency, however, they are only efficient while the cutting head is open and the full capacity of the pump is being used. When the head closes while the material is being loaded, unloaded, and re-loaded, or while the machine positions for the next cut, almost all of the energy is directed over a relief valve, literally sending power, water and money down the drain. Intensifier water jet pumps are inherently less efficient due to the power required to simply run the hydraulic system. They also use a large percentage of their power regardless whether cutting or idle, as the hydraulic oil is passed over a relief valve in the hydraulic system. The Quantum® only ever uses the power required for the cutting process. This means that regardless of whether the cutting head is open or closed, or the pressure or flow is reduced, there are no additional power losses.

Duty cycles equate to the percentage of time that the cutting head is open, cutting, and actually removing material. As with any profile cutting machine, a percentage of time is used to positioning the head between cuts and while sheets are being loaded and unloaded. Typical duty cycles range from 90% for heavy plate cutting, down to 20% for plastics, foams and automotive trim components. Most common waterjet applications such as metal cutting, fabrication, stone cutting, and glass cutting run at about 60% duty cycle.

The high level of efficiency achieved by the Quantum® dramatically reduces the energy consumed and the water required. For example, a typical company running a single head waterjet cutting machine with the Quantum®, for a single shift for a year, will save approximately 32,000 kW hrs, saving around $6,080/year in electricity charges, and reducing harmful CO2 greenhouse gases by a staggering 20 tons/yr. There are also considerable water consumption savings as a result of the increased efficiency. For the same example, savings of approximately 290,000 gallons/yr can be achieved, resulting in savings of around $3,019/year.

*Figures are based on a comparison with a typical 50 hp intensifier pump running at 60% duty cycle.

download

Breakdown of the Servo Technology used by NASA

Complete Machine Specifications

Key Benefits on Why The Quantum® is the Future in Waterjet Pumping Technology

Quantum® videos

Quantum®

The Future in Waterjet Cutting Technology

Quantum®

Seal change fastest in the industry

VIEW OUR IntecTMG2 series waterjet machines