How a waterjet and plasma owner like Hydro-Blade expands its business with the help of Techni Waterjet

STEEL

STAINLESS STEEL

ALUMINUM

ALLOY

Minimise turnaround time

Minimise operating costs

Minimise maintenance and downtime

Flattened the learning curve with user-friendly software and pump interface

Significant reduction of power, water, and abrasive consumption

Ability to prevent issues thanks to highly advanced technologies

Industry of Reference and Business Model

Since 2008, Hydro-Blade has been dedicated to providing quality waterjet cutting to Louisiana, Texas, New Mexico, Mississippi, Alabama, and more.

Industries they serve include: Aerospace, Automotive, Consumer Products, Defense, Education, Electronics, Energy, Hardware, Industrial, Marine, Medical, Oil and Gas, Robotics, and more.

In 2018, Hydro-Blade underwent a merger with Paragon Metalworks. This merger has enabled Hydro-Blade to become a full-scale machine shop and manufacturing facility which offers: fabrication, CNC machining, waterjet cutting, plasma cutting, and metal processing.

Keeping up with a fast-paced modern market

In order to be able to offer such a great variety of services, the owners Ben Chauvin and Charles Green needed to invest in new machinery with the latest technology.

As they already owned an older waterjet machine, Chauvin recognized this type of technology an ideal solution for their applications, nonetheless, they required something more capable, advanced and user-friendly to cope with the modern fast-paced market.

Seeing what else is out there led Hydro-Blade to Techni Waterjet®, Chauvin was initially attracted to Techni waterjets’ ease of maintenance, usability, and low cost of consumables.

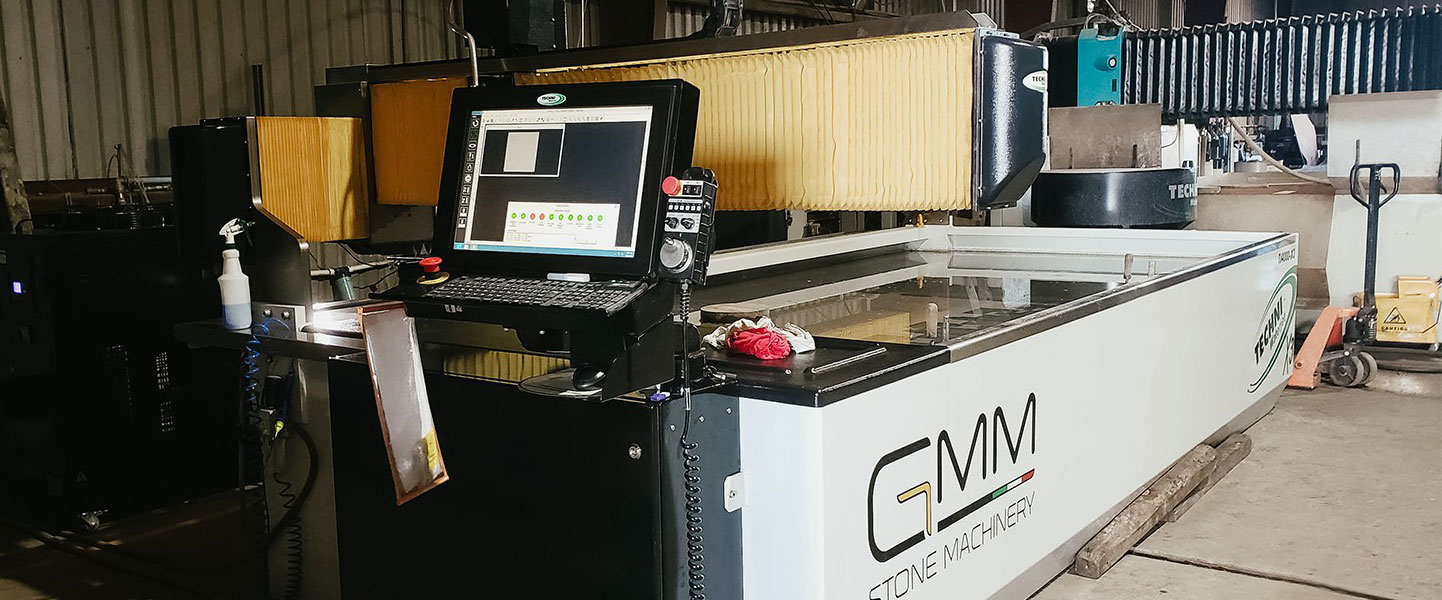

After visiting machine shops equipped with Techni waterjets and consulting with Kearney Machinery, Techni’s local dealer, Chauvin decided the Intec-G2 i612 (formerly called TJ4000-X3) was the best fit for Hydro-Blade.

Improvements Over Old Waterjet Technologies

“In the time trials that we’ve done, it’s cutting faster than a larger jet would.”

In fact, the Intec-G2 was able to complete some jobs up to 40% faster than Hydro-Blade’s previous waterjets. Techni’s Quantum® Electric Servo Pump gets most of the credit for this increase in productivity. The ESP is very unique in the marketplace and the efficiencies designed in, allow for faster cutting, easier maintenance and more runtime between maintenance cycles.

Techni’s Tech-Sense technology monitors the cutting head and pauses the job before any blockage. Tech-Sense, along with the ability to monitor the job from any smart device, has allowed Hydro-Blade to run the machine with their lights out without worrying about wasting costs by way of scrap or consumables.

“A mix of the man running the machine, and the machine running the man. It can save me 30 minutes to two hours trying to diagnose the problem, and that equates to saving money.”

Besides the machine itself, Chauvin knows that service is just as important.

“I don’t care what type of machinery you have. If you don’t have the service to back it up, I don’t even want to have a conversation.”

Though Hydro-Blade hasn’t had their i612-G2 for long, the shop has already seen improvements in their workflow, especially when it comes to ease-of-use.

Chauvin said:

“I took one of my guys that was a plasma operator that had very little experience on waterjets. We put the Techni on the floor, brought him in, and had him go through the learning process. He’s stepped up to be my lead operator. When you can have somebody that’s sweeping the floor, and in three or four hours have them running the machine, it’s a pretty significant move.”

Thinking Their Way into the Future

Hydro-Blade expects to continue expanding their shop and broadening its footprint as well as planning on increasing both workers and workspace soon. They also plan on becoming more of a product-based company, manufacturing other companies’ products and even designing their own.

So far, Techni’s i612-G2 is making Hydro-Blades growth possible and the shop plans on purchasing additional Techni waterjets.

“I can tell you what’s needed and not needed for our applications. Techni fit the bill and the price point was there. It made sense.”

– Ben Chauvin, Co-owner of Hydro-Blade Waterjets.