Precision machining is a process that lies at the heart of every tool and component we rely on each day.

From the devices that power our homes to the vehicles we travel in, this method is fundamental to manufacturing parts with exceptional precision and efficiency.

Using sophisticated CNC machines, this craft turns a simple piece of metal into critical components used in industries as varied as automotive, aerospace, and electronics.

In 2025, the precision machining sector is not only thriving but expanding rapidly, with its market value projected to increase to approximately USD 180.25 billion by 2030, growing at a CAGR of 7.8% from 2024 to 2030.

This growth highlights a broader trend: a rising demand for components that are not only precise but also consistent and reliable, with tolerances sometimes as narrow as ±0.0001 inches.

In this article, we’ll focus on simplifying the mechanics behind precision machining, how it’s revolutionizing manufacturing, and why its accuracy is so crucial for the modern world.

What is Precision Machining?

Precision machining is a CNC machining process that removes excess material from a workpiece, yielding parts that adhere to extremely tight dimensional tolerances. It involves CNC (Computer Numerical Control) tools and techniques that rely on digital blueprints from CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to dictate every cut and dimension.

These specifications ensure parts fit perfectly, highlighting precision machining’s crucial role in industries where exactness is non-negotiable.

The integration of high-speed robotics and advanced tooling with skilled operation underscores a commitment to consistency and repeatability, hallmarks of modern precision machining.

What is the History and Evolution of Precision Machining?

The journey of precision machining began long before the digital age, tracing back to manual methods that leveraged early machine tools. The introduction of CNC technology in the mid-20th century marked a transformative period, enhancing precision with programmable, automated tool movements.

By the 1970s, these capabilities evolved further with multi-axis CNC machines, which significantly reduced manual labor and margin for error, allowing for the creation of complex geometries with unparalleled accuracy.

Today, the field continues to advance with innovations in tooling materials like carbide and diamond, embracing Industry 4.0 technologies that integrate automation and data exchange to refine processes further.

How Does Precision Machining Work?

Precision machining operates through a subtractive manufacturing process, where material is methodically removed from a workpiece to achieve the desired geometry and tolerances.

The process utilizes advanced machinery such as CNC (Computer Numerical Control) machines, which integrate rotary cutters, turning tools, or electrical discharges to sculpt the material precisely.

The success of precision machining hinges on several critical factors:

- Operator Skill and Machine Condition: Skilled machinists ensure that the machines are optimally operated and maintained to produce components with the required precision.

- High-Quality Cutting Tools: The tools used are specifically designed to handle the rigorous demands of removing material at high accuracy and speed.

- Machine Tool Calibration: Essential for maintaining consistency in the manufactured parts, calibration aligns the machinery to function according to exact specifications.

- Computerized Instructions: CNC machines operate based on G-codes and M-codes, which direct the machine’s movements and operations, ensuring each part matches the digital blueprints exactly.

What are the Steps in the Precision Machining Process?

Throughout these steps, precision machining utilizes a combination of technological innovation and meticulous attention to detail, ensuring that each part produced meets stringent industry standards and customer requirements.

Step 1: Design the Graphical Model

The first step in precision machining begins with the creation of conceptual or hand-drawn sketches to capture the basic geometry of the part. These initial designs are crucial for visualizing the final product’s form and function.

Subsequently, these sketches are transformed into more detailed 2D or 3D digital models using CAD (Computer-Aided Design) software. This software allows machinists to layout precise dimensions and tolerances, ensuring that every aspect of the design is mapped out before machining begins.

Step 2: Convert CAD to CAM

Once the CAD model is completed, the design must be converted into a format that machining tools can interpret. This is where CAM (Computer-Aided Manufacturing) software comes into play.

CAM software translates the CAD model data into machine-readable instructions, known as G-code and M-code. G-code guides the machine on the path and coordinates of the tooling, while M-codes manage auxiliary functions such as turning the coolant on or off during the machining process.

Step 3: Machine Setup

Before the machining process can begin, it is imperative to set up the machine correctly. This involves calibrating the equipment to ensure precision and securing the workpiece using appropriate fixturing tools such as vises, chucks, and guide bushes—particularly in complex machining operations like Swiss Machining. It’s also crucial to adjust the machine parameters, including spindle speeds, feed rates, and coolant flow, to optimize the machining environment.

Step 4: Execute the Machining

With everything set, the CNC machine can start the machining process. The program runs autonomously, controlling the cutting speed, feed rate, and tool movements with precision.

During this phase, it’s vital to monitor the operation closely, especially during the initial run, to ensure that the part is being machined to the correct tolerances and to make any necessary adjustments or tool changes promptly.

Step 5: Completion

After the machining is complete, the part may require secondary processes like polishing or grinding to achieve the desired finish and dimensions. The final step is a thorough quality inspection to verify that the part meets all specified tolerances and quality standards before it is deemed ready for use or assembly.

This ensures that the part functions correctly in its designated application, maintaining the integrity and reliability of the product.

What are the Key Precision Machining Parameters?

Precision machining parameters are critical for achieving the desired precision and quality of machined parts, especially in industries requiring high levels of accuracy such as aerospace, medical, and defense.

Below are the essential parameters that significantly influence the precision machining process:

- Machining Tolerances: Refers to the allowable limit of variation in a physical dimension of a machined part.

- Surface Finish: This involves the texture of the machined surface and is crucial for the functionality and aesthetics of the part.

- Cutting Speed: The speed at which the cutting tool makes contact with the material, affecting the finish and tool life.

- Feed Rate: The rate at which the cutting tool and the workpiece move in relation to each other, crucial for the rate of material removal and the quality of the finished surface.

- Depth of Cut: This indicates the depth of the tool as it cuts into the material, affecting the load on the tool and the efficiency of the cutting process.

- Vibration Control: Essential for maintaining the stability of the machining process, reducing wear and tear on tools, and improving the quality of the machined part.

What are Precision Machining Tolerances?

Machining tolerances are the permissible limits of variation in the physical dimensions of machined parts. Precision machining tolerances are critical for ensuring that parts fit together correctly in assemblies and function as intended.

In high-precision setups such as Swiss Machining, tolerances can reach as tight as ±0.0001 inches. However, standard CNC machining setups generally achieve tolerances ranging from ±0.005 to ±0.008 inches.

Tolerances are often categorized as follows:

- Unilateral Tolerance: Where variation is allowed in only one direction from the specified dimension.

- Bilateral Tolerance: Where variation is allowed in both directions from the specified dimension.

- Compound Tolerance: Applies to scenarios where multiple different tolerances are applied to different dimensions of the same part.

- Limit Dimensions: The maximum and minimum allowable dimensions.

What are the Different Precision Machining Methods?

Precision machining encompasses various techniques that ensure materials are shaped with utmost accuracy and intricacy. Among these methods, waterjet cutting stands out for its ability to cut materials cleanly without the heat-induced deformations typical of other methods. Below are detailed insights into some commonly used precision machining methods:

CNC Milling

CNC milling utilizes computer numerical control (CNC) to operate machine tools for milling, one of the most common forms of precision machining. CNC milling machines employ rotary cutters to remove material from a workpiece, creating highly detailed parts to exact specifications.

Advantages:

- High Precision: Achieves complex geometries with exact tolerances.

- Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

- Scalability: Efficiently produces both single prototypes and high-volume production runs.

Applications:

- Complex Parts Production: Ideal for components with intricate designs such as engine parts, mold tooling, and intricate brackets.

- Prototyping: Quickly creates prototypes to test designs before mass production.

- Customization: Easily adapts to produce bespoke parts for specialized applications.

CNC Turning

CNC Turning is a form of precision machining where the workpiece is rotated at high speeds while a stationary cutting tool removes material, shaping it into the desired form. This method is particularly effective for creating cylindrical parts and operates using both vertical and horizontal configurations.

Advantages:

- Efficiency: Excellent for large production runs of cylindrical components.

- Precision: Achieves tight tolerances and high-quality surface finishes.

Applications:

- Shafts and Cylinders: Commonly used for automotive axles, electrical motor components, and more.

- Flanged Components: Produces precise flanges with specific profiles for various industrial applications.

CNC Drilling

CNC drilling is a precision machining process that utilizes computer numerical control to drive drills into a material, creating cylindrical holes. This method is integral in the manufacturing of parts that require precise hole specifications, often needed for assembly or fastener insertion. CNC drilling machines vary from simple bench-mounted equipment to complex multi-axis setups.

Advantages:

- High Precision: Ensures holes are consistently placed and sized as per specifications.

- Efficiency: Capable of handling multiple drilling operations simultaneously, which reduces production time.

- Versatility: Can be used on a variety of materials including metals, plastics, and composites.

Applications:

- Component Assembly: Creating holes for screws, bolts, and rivets.

- Electrical Connections: Drilling entry and exit points for wiring in electrical assemblies.

- Fluid Systems: Making ports and channels in hydraulic components.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM), also known as spark machining, involves the use of electrical sparks to mold a material into a specific shape. This process can cut extremely hard metals and intricate designs that are challenging to achieve with conventional machining. EDM is characterized by the absence of direct contact between the tool and the workpiece, which minimizes mechanical stress.

Advantages:

- Precision: Capable of producing complex shapes with high precision and fine detail.

- Material Versatility: Effective on hard metals that are difficult to machine using traditional techniques.

- Surface Quality: Provides excellent surface finish, reducing the need for post-machining surface treatments.

Applications:

- Create Intricate Molds and Dies: Especially useful in the tool and die industry for detailed cavities and patterns.

- Machine Complex Geometries: Allows for the production of small, intricate parts used in aerospace and medical devices.

- Produce Fine Features: Able to achieve fine features and tight tolerances in hardened materials.

Swiss Machining

Swiss Machining refers to a precision machining process that supports the production of very small, intricate parts by allowing material to move in and out of the tooling area, which is stabilized by a guide bushing. This method excels in operations requiring extreme accuracy and is capable of reaching tolerances as tight as ±0.0001 inches.

Advantages:

- High Precision: Ideal for medical and aerospace components requiring micron-level accuracy.

- Efficiency: Minimizes material wastage and maximizes production efficiency.

Applications:

- Micro-components: Produces parts like watch gears, medical implants, and connector pins.

- Complex Geometries: Handles parts with complex axial and radial features effectively.

Multi-axis CNC Machining

Multi-axis CNC machining extends the capabilities of standard CNC technology by utilizing 4-axis and 5-axis machines. These advanced machines can rotate a part along multiple axes to enable cutting from several angles, enhancing the complexity and precision of the machining process.

Advantages:

- Enhanced Precision: Maintains tight tolerances even with complex geometries.

- Increased Productivity: Reduces setup time by completing parts in fewer operations.

- Complex Designs: Capable of producing intricate parts without secondary operations.

Applications:

- Aerospace Components: Produces complex parts such as airfoils and turbine blades.

- Automotive Industry: Used for prototyping and production of custom automotive components.

- Medical Devices: Ideal for creating orthopedic implants and other precision medical instruments.

Precision Grinding

Precision grinding is a machining process that uses a rotating grinding wheel to achieve extremely fine surface finishes and precise tolerances, typically less than 0.001 inches per side. This method is commonly used as a finishing process to refine the surface quality and dimensions of a part.

Advantages:

- Surface Finish: Achieves a smooth, mirror-like finish on metals and other materials.

- Dimensional Accuracy: Ensures parts meet strict dimensional requirements.

- Material Versatility: Effective on hard, tough materials including hardened steels and hard metals.

Applications:

- Surface Finishing: Commonly used to finish flat, cylindrical, or contoured surfaces.

- Tight Tolerances: Essential for applications requiring high precision, such as bearing surfaces and gear teeth.

- Wear Resistance: Enhances the longevity of parts by improving their surface hardness and resistance to wear.

CNC Laser Cutting

CNC laser cutting employs high-powered lasers to cut materials with exceptional precision. This technique is instrumental in industries requiring intricate cuts and fine details. Machines designed for laser cutting are equipped with focused light beams that can easily handle various materials, from metals to non-metals, with minimal thermal distortion.

Advantages:

- Precision and Versatility: Allows for cutting complex shapes without physical contact with the material, minimizing mechanical wear and material contamination.

- Speed and Efficiency: Rapid processing speeds and high repeatability make it suitable for high-volume production runs.

- Low Thermal Impact: Reduces the risk of material warping or structural changes due to heat.

Applications:

- Intricate component shapes in the electronics and aerospace industries.

- Engraving and detailed artwork on surfaces like wood and acrylic.

- Fabrication of intricate designs in the jewelry and decorative industries.

Waterjet Cutting

Waterjet cutting utilizes a high-pressure stream of water, often combined with abrasive materials, to cut a wide range of materials. This method is celebrated for its ability to cut without introducing heat, thus maintaining the integrity of the material’s structure.

Advantages:

- No Heat-Affected Zone (HAZ): Prevents material tempering or warping.

- Material Versatility: Effective on a variety of different materials like metals, stones, food, wood, plastics, paper, fiberglass and composites.

- Precision: Capable of achieving tight tolerances similar to those found in other precision CNC processes.

Applications:

- Cutting thick metal plates for automotive and aerospace components.

- Creating intricate patterns in stone and tile for architecture and flooring.

- Fabricating components used in industries sensitive to material properties, such as aerospace and art.

Ultrasonic Machining

Ultrasonic machining (USM) involves the use of ultrasonic waves and an abrasive slurry to erode material from the workpiece. This process is ideal for hard, brittle materials like ceramics and glass.

Advantages:

- No Thermal Damage: Allows machining of temperature-sensitive materials.

- High Precision: Achieves fine features and tolerances that are difficult with conventional machining.

- Complex Geometries: Capable of producing intricate details and complex patterns.

Applications:

- Machining hard and brittle aerospace materials, such as ceramics and hardened alloys.

- Creating complex features in micro-electromechanical systems (MEMS).

- Detailed engraving and drilling of small, fragile components in the electronics industry.

Micro-Machining

Micro-machining stands out as a precision engineering method where small and intricate parts are fabricated with dimensions typically in the micrometer range. This method employs specialized micro-machining centers that are essentially scaled-down CNC machines capable of extremely fine tolerances and surface finishes.

Advantages:

- High Precision: Capable of achieving details and tolerances not possible with standard machining.

- Complex Geometries: Allows for the production of extremely small and complex shapes, crucial for micro-electronics and medical devices.

Applications:

- Manufacturing micro-scale components like electronic connectors and microfluidic devices.

- Creating detailed features in medical implants and surgical instruments.

- Producing tiny molds for micro injection molding.

In-Mold Machining

In-mold machining integrates the precision machining of mold cavities directly within the tooling process, primarily used in the plastic injection molding industry. This technique employs high-precision CNC mills and EDM machines to create and refine mold designs with intricate details and superior finishes.

Advantages:

- Efficiency in Mold Making: Enhances the mold’s accuracy and lifespan by precisely machining complex geometries.

- Cost-Effectiveness: Reduces the need for post-molding modifications and increases the repeatability of mold production.

Applications:

- Creating detailed and complex features directly in new molds.

- Refining existing molds to extend their usable life or alter their design.

- Producing molds for highly detailed plastic parts used in automotive and consumer electronics.

CNC Plasma Cutting

CNC plasma cutting is distinguished by its use of a plasma torch to cut through electrically conductive materials with exceptional speed and precision. This process is facilitated by CNC machines that guide the plasma torch over the material according to digitally pre-programmed patterns.

Advantages:

- Rapid Cutting Speed: Significantly faster than traditional mechanical cutting, suitable for large-scale production.

- Versatility with Materials: Efficiently cuts through various metals including steel, stainless steel, and aluminum.

Applications:

- Quickly slicing through thick metal sheets in industrial manufacturing settings.

- Producing large components for the construction and shipbuilding industries.

- Fabricating artistic metal designs and signages with speed and precision.

Which are the Best Precision Machining Technologies?

In precision machining, various technologies stand out for their specific strengths, making them ideal for certain applications over others.

Understanding these strengths helps in selecting the best machining method for particular manufacturing needs.

- CNC Milling: Renowned for its versatility, CNC milling is exceptional for creating complex surfaces on diverse materials. It employs rotary cutters and can operate along multiple axes—3-axis, 4-axis, or 5-axis machines—making it perfect for parts that require intricate detailing and complex geometries.

- Swiss Machining: This method shines when it comes to producing miniature, ultra-precise components, achieving tolerances as tight as ±0.0001 inches. It is especially favored in the medical and aerospace industries where such extreme precision is mandatory.

- Multi-Axis CNC Machining: Known for its ability to enhance productivity and accuracy, multi-axis machining (including 4-axis and 5-axis CNC milling) allows for cutting from multiple angles in a single setup. This capability significantly reduces production time while maintaining extremely close tolerances, ideal for complex aerospace components and intricate molds.

- Waterjet Cutting: Preferred for its ability to cut without introducing heat-affected zones, waterjet cutting uses a high-pressure stream of water, sometimes with added abrasives, to cut materials. This method is best for materials that are sensitive to high temperatures generated by other cutting methods, such as certain metals, plastics, and composites.

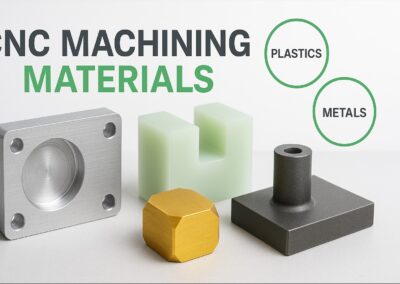

What Materials are Suitable for Precision Machining?

Precision machining processes vary widely, but the choice of material often dictates the success of the final product. Below, you will find a comprehensive list of materials suitable for precision machining and why they are favored:

- Aluminum: Known for its lightweight and strong properties, aluminum is easy to machine and is often used in aerospace and automotive industries due to its excellent strength-to-weight ratio.

- Steel: This is a common choice for its durability and strength, making it ideal for heavy-duty applications in construction and automotive industries.

- Stainless Steel: Highly resistant to corrosion and staining, stainless steel is preferred in medical and food processing industries.

- Brass: Easy to machine and corrosion resistant, brass is commonly used in plumbing and electrical applications.

- Copper: Best known for its electrical conductivity, copper is often used in electrical components and heat exchangers.

- Titanium: Known for its strength, lightweight, and corrosion resistance, titanium is crucial in aerospace and medical sectors.

- Magnesium: Being the lightest structural metal, magnesium is favored for its machining ease and strength, commonly used in aerospace applications.

- Inconel: This superalloy is favored for its ability to withstand extreme environments, making it ideal for aerospace and chemical processing industries.

- Plastics: Materials like ABS, PC, PMMA, and POM are widely used due to their ease of machining and versatility in applications from automotive to consumer products.

- Ceramics: While hard and brittle, ceramics can achieve high precision with specialized tooling but are prone to cracking.

- Glass: Requires specific abrasive tooling for machining, used in applications requiring high purity and optical clarity.

- Composites: Ideal for customized applications, composites can be tailored for specific strength and weight requirements but require specialized machining.

- Natural Materials (e.g., wood): Easily machined but less common in high-tolerance applications, used primarily in consumer goods.

- Exotic Alloys: Including carbon steel, tool steel, and nickel alloys, these materials are prevalent in high-performance industries due to their unique properties such as high strength and resistance to wear and tear.

- Bronze: Often used for its excellent conductivity and wear resistance, particularly in bearings and bushings.

- Graphite: While it is machined for specialized applications like electrical discharge machining electrodes, graphite requires careful dust management.

What Tools Are Required for Precision Machining?

Precision machining utilizes a variety of specialized tools that enable manufacturers to produce intricate and precise components. These tools are fundamental in machining operations, ranging from cutting and shaping to finishing and inspecting.

Cutting Tools

Cutting tools are essential for machining operations, each designed for specific functions within the manufacturing process:

- End Mills: Crucial for milling operations, they cut laterally and are available in various designs for different materials and patterns.

- Drills: Used for making round holes or driving fasteners.

- Reamers: Enhance hole quality and dimensions with high precision.

- Taps: Create internal threads within holes to accommodate screws or bolts.

- Boring Bars: Used for enlarging holes and achieving precise diameters.

- Turning Inserts: Detachable cutting surfaces used in lathes for turning operations.

Additional Information:

- Tool Coatings: Tools are often coated with materials like TiN (Titanium Nitride), TiCN (Titanium Carbonitride), or diamond to extend their life and enhance performance on abrasive materials.

- High-Precision Inserts and Multi-Flute End Mills: These are particularly used for achieving ultra-fine finishes on workpieces.

Measurement and Inspection Tools

Accurate measurement and inspection tools are critical to ensure that machined parts meet stringent quality standards:

- Calipers: Provide quick and accurate measurements of object dimensions.

- Micrometers: Offer precise measurement capabilities, crucial for detailed inspection.

- Dial Indicators: Used for precise measurement of small distances in mechanical engineering setups.

- Coordinate Measuring Machines (CMM): These sophisticated machines provide detailed 3D measurements of complex geometries.

- Height Gauges: Measure and mark item heights with high accuracy.

- Surface Plates: Provide a true, flat surface to check flatness and support inspection work.

Additional Information:

- Accurate Inspection Tools: They are vital for confirming that parts meet the tight tolerance requirements essential in high-precision industries.

- Digital Probing Systems: These advanced systems can transfer real-time measurement data directly to CNC machine controls, enabling on-the-fly adjustments and ensuring continuous precision throughout the production process.

Workholding Devices

Workholding devices are crucial for securing workpieces during machining processes, ensuring stability, precision, and safety. Key types of workholding tools include:

- Vises: Provide a stable grip for workpieces during machining operations, crucial for maintaining precision.

- Chucks: Used primarily in lathes, they hold workpieces securely by expanding and contracting to fit various sizes and shapes.

- Clamps: Offer a quick and versatile method of securing a workpiece to a surface or machine table.

- Fixtures: Custom-designed to hold workpieces in a fixed location, fixtures are essential for batch production and maintaining consistency.

- Jigs: Guide the cutting tools, allowing for repeatability and accuracy in processes like drilling and milling.

Additional Points:

- Minimizing Vibration: Secure fixturing is key to minimizing vibration and movement, which helps maintain dimensional integrity throughout the machining process.

- Specialized Clamping Systems: Collet systems and custom soft jaws are particularly beneficial for clamping delicate or oddly shaped parts without causing distortion. These systems are designed to provide even pressure distribution, reducing the risk of damaging the workpiece.

What Software Is Used in Precision Machining?

In precision machining, the software you use is as critical as the hardware. The right software not only facilitates design but also ensures precision in manufacturing through automation and fine control.

- CAD (Computer-Aided Design) Software: Essential for drafting and designing components. CAD software allows for the detailed creation of part geometries before machining.

- CAM (Computer-Aided Manufacturing) Software: Converts CAD models into CNC machine instructions. CAM software is crucial for planning, simulating, and executing machining operations.

- CNC (Computer Numerical Control) Software: Directly controls machine tools via programmable automation. This software dictates the movement of tools on various axes, ensuring high precision and repeatability.

- Simulation and Analysis Software: Allows for the virtual testing of CNC programs and machining processes to identify potential errors and inefficiencies before actual machining.

- Inspection and Quality Control Software: Used to ensure parts meet stringent specifications through detailed measurements and statistical monitoring.

- ERP (Enterprise Resource Planning) Software for Manufacturing: Integrates core business processes in manufacturing, helping streamline operations from order booking through production to delivery.

What are the Applications of Precision Machining?

Precision machining serves a broad spectrum of industries, each with unique requirements that this technology adeptly meets.

- Aerospace and Defense: These sectors demand machining of the hardest alloys and require extremely tight tolerances for critical components like engine parts and avionics.

- Medical Devices and Implants: Precision is paramount as these products often involve biocompatible materials and necessitate micro-scale accuracy to ensure patient safety and device efficacy.

- Prototyping: Offers unmatched repeatability which is crucial for testing the fit and function of new designs, thereby accelerating innovation and development cycles.

- Marine and Agricultural Equipment: Relies on high-precision parts to ensure the reliability and durability of machinery such as pumps, shafts, and engine components.

- Renewable Energy Systems: Components for solar panels and wind turbines must be machined to exact specifications to ensure efficiency and longevity in harsh environmental conditions.

Automotive Industry

CNC machining, a force in the automotive sector, allows for the production of complex parts with tight tolerances essential for vehicle performance and safety. Components such as engine parts, transmission components, and suspension systems are commonly produced using advanced machining techniques, ensuring they meet rigorous industry standards.

- Enhanced Component Precision: Achieves tight tolerances necessary for high-performance automotive parts.

- Improved Production Efficiency: CNC machines streamline production processes, reducing time and cost.

- Material Versatility: Capable of machining a variety of materials from aluminum to high-strength alloys used in automotive applications.

Medical Industry

In the medical industry, precision machining is crucial for creating complex, high-precision instruments and implants. Utilizing materials that are biocompatible and capable of withstanding rigorous sterilization processes, machining processes must adhere to stringent regulatory standards. CNC precision machining is used to manufacture joint replacements, surgical instruments, and other critical devices, ensuring patient safety and product reliability.

- Micro-machining Capabilities: Allows for the production of tiny, complex features crucial for medical devices.

- High Precision and Reliability: Meets the exacting standards required for medical applications.

- Adaptability to Biocompatible Materials: Machines a range of materials that are safe for medical use.

Defense Industry

The defense industry relies on precision machining for the production of high-quality, durable parts that can withstand extreme conditions. Precision machining processes are employed to create components of weaponry, vehicles, and aerospace applications where failure is not an option. The ability to work with a variety of materials, including advanced composites and titanium, is essential for meeting the defense sector’s unique requirements.

- Durability and Precision: Ensures components can endure harsh operational environments.

- Complex Part Production: Manufactures parts with complex geometries that are often required in defense applications.

- Material Diversity: Handles everything from lightweight alloys to armor plate materials.

Electronics Industry

From smartphone casings to PCB fixtures, precision machining helps achieve the miniature and precise parts needed for modern electronics. The use of materials such as copper, aluminum, and conductive composites is common, emphasizing the need for precision and minimal error margin.

- High Precision for Small Components: Essential for the miniaturization of electronic devices.

- Surface Smoothness: Achieves the high-quality finishes required for electronic components.

- Rapid Prototyping: Allows for quick development and iteration of new electronic designs.

Robotics

CNC machining techniques are extensively used to create custom parts that require exact dimensions and tolerances, which are essential for the efficient performance of robots. This technology facilitates the development of complex geometries that are often involved in robotic components, from articulating arms to sensor mounts, ensuring seamless integration and functionality.

- Component Uniformity and Precision: Essential for the interoperability of robotic systems.

- Complex Part Production: Allows for the creation of intricate designs necessary for advanced robotics.

- Material Versatility: Capable of handling a diverse array of materials, from lightweight aluminum to robust titanium, used in various robotic applications.

Optics

The use of precision machining ensures that optical components like lenses, mirror mounts, and optical enclosures meet high standards of clarity and performance. CNC machining, in particular, provides the precision necessary for ensuring that light pathways are not disrupted by imperfections, which is crucial for the manufacturing of optical instruments.

- High Surface Quality: Achieves smooth finishes that are imperative for optical clarity.

- Precise Dimensional Tolerance: Ensures that components fit together perfectly to maintain the integrity of optical systems.

- Customization Ability: Allows for the production of bespoke components used in specialized optical applications.

Prototyping

Precision machining is a cornerstone in prototyping for various industries, providing the speed and accuracy needed to bring new designs to life swiftly. It allows engineers and designers to rapidly iterate on their designs by creating precise prototypes that reflect the final product. This capability is crucial for testing form, fit, and function before committing to full-scale production, significantly reducing the time and cost associated with product development.

- Rapid Turnaround: Enables quick production of prototypes to accelerate the development process.

- Exact Replication of Final Parts: Ensures that the prototype accurately represents the intended design.

- Material Flexibility: Machines a wide range of materials, mirroring the properties of the materials that will be used in final production.

Telecommunications

From fiber optic housings to satellite components, precision machining ensures that all parts meet exact specifications to maintain signal integrity and connectivity. The ability to work with a variety of conductive materials and the precision to create complex, minute features make precision machining indispensable in this field.

- High Precision and Consistency: Necessary to maintain the quality and reliability of communication systems.

- Complex Geometries: Enables the production of intricate components critical for modern telecommunications equipment.

- Conductivity and Durability: Machines materials that meet the electrical and environmental demands of telecommunications applications.

Oil and Gas Industry

Oil and gas industry relies on precision machining for the manufacturing of drilling equipment, valves, and other complex components that require high durability and precision. The use of advanced CNC machining ensures that these components meet stringent safety and performance standards, which is vital in an industry where equipment failure can have severe consequences.

- High-Pressure Resistance: Components are designed to endure the intense pressures found in oil extraction.

- Corrosion Resistance: Materials and finishes are selected for their ability to withstand harsh chemicals and environments.

- Complex Geometries: Enables the production of intricate shapes necessary for advanced drilling and extraction technologies.

Industrial Equipment Manufacturing

In industrial equipment manufacturing, precision machining is used to produce large-scale machinery parts that require exact tolerances to function correctly. These components often include gears, bolts, and structural frames for machinery used in construction, agriculture, and manufacturing processes. Precision machining allows for the high degree of accuracy needed in these applications, ensuring equipment reliability and safety.

- Durability and Strength: Critical for components that will undergo intense operational stresses.

- Customization: Machining provides the flexibility to produce parts tailored to specific industrial applications.

- Efficiency: Enhances the operational efficiency of machinery with precisely made parts that reduce wear and tear.

Consumer Electronics

Precision machining is used to create parts within smartphones, laptops, and other electronic devices where space is limited, and precision is paramount. This process ensures that components such as connectors, buttons, and casing are perfectly dimensioned to fit together seamlessly, enhancing device performance and durability.

- Miniaturization: Allows for the production of small, complex components essential in modern electronics.

- High Volume Production: Machining can be scaled up to meet the high-demand production rates typical in this industry.

- Aesthetic Quality: Produces components with high-quality finishes that are crucial for consumer appeal.

Renewable Energy

In the renewable energy sector, precision machining is applied in the production of parts for solar panels, wind turbines, and other energy systems. Components like turbine blades and photovoltaic mounts are produced with exact specifications to maximize the efficiency and functionality of energy systems. This method ensures the reliability and effectiveness of equipment used in the capture and conversion of renewable resources.

- Performance Optimization: Critical for components that must perform efficiently to optimize energy capture.

- Weather Resistance: Materials and finishes are selected for durability under variable environmental conditions.

- Component Interoperability: Ensures precise fits for modular systems often used in renewable energy setups.

Tool and Die Manufacturing

Tool and die manufacturing industry demands materials that can endure repetitive cycles without degradation, and precision machining provides the necessary accuracy for tools that produce consistent, high-quality products. The meticulous attention to detail helps in minimizing material waste and maximizing the life span of the tools.

- High Wear Resistance: Tools are designed to withstand high-volume production runs.

- Extreme Accuracy: Essential for the creation of dies and molds that must consistently shape other materials with precision.

- Cost Efficiency: Reduces the overall production costs by extending the life of tools and dies.

What are Precision Machining Advantages?

Precision machining offers benefits that enhance both product quality and operational efficiency. Here’s a closer look at its key advantages:

- Precision and Accuracy: Ensures components are crafted to exact specifications, critical for applications where tight tolerances are non-negotiable.

- Complex Geometries: Capable of producing intricate designs that are impossible to achieve with less advanced techniques.

- Material Suitability: Adaptable to a wide range of materials, from metals to plastics, ensuring optimal material properties are maintained.

- Scalability: Equally effective for one-off prototypes as it is for high-volume production without sacrificing quality.

- Secondary Operations: Reduces the need for subsequent machining, saving time and resources.

- Cost Effectiveness: While the initial setup costs may be high, the longevity and reduced need for rework offset these over time.

- High Repeatability: Delivers consistent results, crucial for large production runs where uniformity is key.

- Speed and Efficiency: Advanced CNC machines can operate continuously, maximizing output and reducing lead times.

- Safety: Minimizes the risk of operator error and enhances workplace safety due to its automated nature.

What are the Disadvantages of Precision Machining?

Despite its extensive benefits, precision machining does come with certain drawbacks that can influence project scope and feasibility:

- Initial Investment: The cost of high-grade CNC machinery can be prohibitively expensive, often exceeding $100,000 for multi-axis systems or Swiss-style lathes.

- Dimensional Limits: There are inherent limitations on the size and complexity of components that can be machined, dictated by the capabilities of the CNC equipment.

- Lead Times: Projects involving complex setups or custom tooling can experience extended lead times.

- Complex Programming: Requires advanced programming skills to effectively harness the technology, necessitating highly skilled operators.

What are Some Common Problems and Defects with Precision Machining?

Precision machining, while highly effective, can encounter several challenges that may impact the quality and efficiency of production. Understanding these issues is key to maintaining the high standards this process promises:

- Chatter: Vibrations that result in imperfect finishes. Can be mitigated by ensuring stable tooling and optimal cutting conditions.

- Tool Wear/Breakage: Reduces machining accuracy. Regular tool maintenance and choosing the correct tool material for the job can prevent this.

- Thermal Deformation: Heat generated during machining can alter material dimensions. Employing consistent coolant flow and temperature control helps maintain accuracy.

- Inaccurate Workholding: Leads to part misalignment. Using precise and stable fixturing systems is essential.

- Programming Errors: Can cause defects or machine crashes. Thorough simulation and verification of CNC programs before actual production runs are crucial.

How to Choose the Right Precision Machining Company?

Selecting the right precision machining service is pivotal for achieving desired outcomes. Here are key factors to consider:

- Experience with Specific Materials and Tolerances: Ensures the company can handle your project’s unique requirements.

- Multi-axis/Swiss Machining Capabilities: Necessary for projects demanding very tight tolerances.

- Quality Control Certifications: Look for ISO certifications which indicate standardized quality and reliability.

- Advanced Inspection Equipment: Ensures that the company can accurately measure and maintain quality throughout production.

- Production Capacity and Lead Times: Important to meet your deadlines.

- Track Record of On-Time Delivery: Indicates reliability and efficiency.

Should You Outsource Precision Machined Parts or Do It In-House?

Deciding between outsourcing precision machined parts and producing them in-house involves several considerations:

- Cost Efficiency: Outsourcing can significantly reduce the need for investment in expensive CNC machinery and specialized staff, especially beneficial for complex parts requiring high-precision.

- Control Over Production: In-house machining provides greater control over production schedules and lead times.

- Capital Investment: Significant investment in machinery, maintenance, and skilled labor is required for in-house operations.

- Flexibility for Growth: Outsourcing is ideal for smaller or specialized projects, while in-house may be more cost-effective at scale once the demand justifies the investment.

What are the Typical Costs for Precision Machining?

Precision machining involves costs influenced by various factors that play a crucial role in the final pricing of manufactured parts. Here are some typical costs and the factors affecting them:

- Hourly Rates: These vary significantly, depending on the complexity of the machine. For instance, multi-axis machines may cost 2–3 times more per hour compared to traditional 3-axis setups due to their advanced capabilities.

- Setup and Programming: Both elements require time and expertise, contributing to higher initial costs. Thorough programming is crucial to avoid costly errors during production.

- Material Selection and Tooling: The choice of materials and tools directly affects costs, with higher-grade materials and specialized tooling leading to increased expenses.

- Required Tolerances: Tighter tolerances demand more precise setups and potentially more expensive equipment.

- Volume Discounts: Ordering larger quantities can significantly reduce the per-part cost, whereas smaller, custom runs typically carry higher per-unit pricing.

What is the Environmental Impact of Precision Machining?

Precision machining, while indispensable in modern manufacturing, carries an environmental footprint that industries strive to minimize. Key impacts and mitigations include:

- Material Usage and Waste Reduction: Precision machining allows for efficient material use, significantly reducing waste. Advances in technology enable the recycling of metal chips and the reuse of raw materials.

- Coolant Management: The disposal and management of coolants are crucial, with proper disposal methods reducing environmental harm.

- Technological Advances: Innovations such as dry machining and minimal lubrication technologies reduce the reliance on copious amounts of coolants, diminishing resource usage.

- Energy Consumption: Automation and optimized tool paths in precision machining reduce idle times, thereby saving energy compared to more traditional, manual methods.

What are Industry Standards and Certifications in Precision Machining?

In precision machining, adhering to industry standards and obtaining relevant certifications are essential for maintaining quality and meeting regulatory requirements. Here are key standards and certifications:

- ISO 9001: A benchmark for quality management systems that demonstrates a company’s ability to consistently meet customer and regulatory requirements.

- AS9100: Specific to the aerospace industry, this standard includes all ISO 9001 requirements with additional aerospace demands.

- International Traffic in Arms Regulations (ITAR): Essential for companies manufacturing defense-related articles.

- RoHS and REACH Compliance: These standards limit hazardous substances in manufacturing processes, crucial for companies operating in or exporting to the European Union.

What are the Latest Trends and Innovations in Precision Machining?

In precision machining, the current landscape is marked by significant innovations and trends that enhance efficiency and precision. Among these are:

- Automation and “Lights-Out” Manufacturing: This trend includes robotic loading and unloading systems that enable factories to operate 24/7 without human intervention, significantly boosting productivity.

- Advanced Multi-Axis and 9-Axis Machines: These sophisticated machines allow for more complex and precise cuts in a single setup, reducing turnaround time and increasing accuracy.

- Hybrid Machining: This emerging method combines additive (3D printing) and subtractive (traditional machining) processes to create parts with complex geometries that were previously unachievable.

- Artificial Intelligence: AI is increasingly used for predictive maintenance to foresee machine failures before they occur and for real-time quality checks during the machining process.

- Advancements in Tooling Materials: Tools coated with diamond-like materials are now more common, offering greater durability and improved finishes on machined parts.

When is Precision Machining Not Necessary?

While precision machining is critical for many applications, there are scenarios where less stringent machining tolerances are adequate and more cost-effective:

- Non-Critical Parts: For components like simple brackets, housings, or covers that do not interface with other complex assemblies, standard machining tolerances are sufficient.

- Cost and Time Savings: Avoiding unnecessary tight tolerances on parts that do not require high precision can significantly reduce manufacturing costs and shorten production times.

Conclusion

Precision machining gives us unmatched accuracy and consistency, essential for creating dependable components used in countless applications. Every day, advancements in machinery, tooling, and technology are expanding what we can achieve, allowing us to push the limits of manufacturing precision.

You’ve seen how, around the world, the demand for intricately engineered parts is skyrocketing. This trend makes precision machining more crucial than ever. It’s what enables manufacturers to meet the rigorous demands of today’s high-tech landscapes. As we look to the future, we’ll continue to rely on these precise techniques to drive innovation and adapt to new challenges across industries.

So, whether you’re directly involved in the manufacturing sector or simply curious about how the items you use daily are made, the progress in precision machining is something we all benefit from. It’s not just about the parts produced; it’s about the possibilities they create.