When we talk about industrial projects, steel is one of the most commonly used harder materials. Workshops typically process steel sheets and blocks by cutting and shaping them to form smaller metal parts.

There are many cutting process options, such as EDM, plasma, and laser cutting.

However, one cutting technology has gained more popularity than others for metal cutting. Waterjet cutting technology has become one of the most widely used steel and metal cutting processes in many industries.

This article explores everything concerning waterjet technology for cutting metals, especially steel, applications, benefits, and other important information.

Can Water Cut Through Steel and Other Metals?

The idea of water cutting hard materials might seem impossible to even imagine. After all, it is water, and we are talking about hard materials like steel, not softer materials like paper or foam.

However, water dynamics change significantly when the speed and high-pressure stream of water is increased sufficiently. In this case, water gains a destructive force that can cut steel and other hard metals better than mechanical cutting tools.

In fact, you might be surprised how effective a waterjet machine is at cutting through steel and how few its limitations are. We will examine some of these limitations later.

For now, let’s explore how a waterjet cuts through steel.

How Does a Water Jet Cut Steel?

Have you noticed how the high-pressure water in a car wash makes your car seem sparkling new within minutes? The pressure that we are talking about here is 1,000 psi. Seems like very high pressure, doesn’t it?

Now when we are talking about high-pressure waterjet cutting, we are talking about water pressures of 50,000 to 60,000 psi. Imagine what this high-pressure water can do to steel! For one thing, water jet cutters can cut through many different materials, including various metals like steel.

The high pressure is accomplished by a high-pressure pump, special high-pressure tubing, and a narrow waterjet nozzle, or cutting head, producing a powerful but tiny jet stream.

At What Pressure Does Water Cut Steel?

The water pressure required can vary, based on the type of abrasive material used, the thickness of abrasives, and the type of steel.

Typically, the range of water pressure will be between 20,000 psi and 55,000 psi. Smaller, harder, and uniform abrasives require a lower water pressure.

How Many Inches of Steel Can Water Jets Cut?

Theoretically, there is no limit to the thickness of steel that advanced water jets can cut. However, when cutting an exceptionally thick piece of steel, the time taken increases significantly, making the process unfeasible.

Therefore, waterjet cutting machines usually cut up to 6 inches of steel. But commercially available machines can handle up to 9 inches as well.

In some applications, advanced abrasive and percussive water jets are modified to cut 18-inch thick steel blocks; however, such thickness isn’t commonly used.

What are the Benefits of Cutting Steel With a Waterjet Cutter?

Now that you know cutting steel is possible with abrasive water jets, the question arises – is there any benefit to the process?

Waterjet cutting has many advantages that make the method effective and preferable to other cutting alternatives.

Waterjet Cutting Benefits

No Heat Affected Zone (HAZ): Unlike other metal cutters, waterjet cutting is a heat-free process, so there is no formation of a heat-affected zone when cutting metal. Heat-affected zones can ruin the integrity of the material, even weakening it near the cut area. Since these zones are eliminated in waterjet cutting, the material can’t overheat, which preserves its integrity.

Superior Finishing

As a result of no heat-affected zone in the workpiece, there is no discoloration, and the cut is cleaner. This creates a superior finish straight off the waterjet table. It also eliminates the need for any secondary finishing, unlike metal cutters that leave the final finished surface needing further finishing.

Cut Quality

The cutting stream from abrasive waterjets moves uniformly through the material, even on minimal kerf cuts. Therefore, the cut quality is precise. In fact, if you run your hand over the cut material, you will notice a smooth edge.

Shapes and Designs

Waterjet cutting has a lot of different adjustment options, and you can control abrasive waterjets with CNC. Water jets are not limited to straight lines, so they can cut many different shapes and designs. This makes waterjet cutting ideal for producing complex components.

Efficiency

With a waterjet cutter, you can stack multiple layers of material on top of each other and cut them together. This increases the efficiency of the actual cutting process.

Precise Cutting Tolerances

The tolerance is the deviation from the intended cut. So it is inversely proportional to the accuracy. Waterjet cutting is one of the most precise methods, resulting in metal parts accurately cut every time.

What are the Typical Applications of Waterjet Cut Steel?

As you have noticed in the previous section, waterjet cutting has a lot of advantages over other cutting methods. This makes waterjet cut metal parts highly sought after for many different applications. Here are a few of these applications:

Engine Components

Due to waterjet cutting being a multi-axis cutting process, 5 or 6-axis waterjet cutters are used to craft intricate shapes such as complex engine parts. Many of the small parts you see in the modern-day automotive industry are created using abrasive waterjet cutting. Its accuracy helps save on machining costs.

Raw Material Processing

Steel is a raw material for many industries. In order to make it ready for transportation and storage, it is often cut into small sheets and blocks. This is done by water jet cutting.

Art and Architecture

Waterjets are used to create various artwork designs by cutting workpieces and punching holes in the material. These designs are used for interior decoration purposes or architectural structures.

Medical Tools

Water jet cutting is a precise cutting method that doesn’t require physical contact of the cutting head with the object to be cut. This makes it ideal for cutting surgical equipment and medical tools.

Best Waterjet Cutters for Steel

Water jet cutting, for sure, has a lot of benefits to offer when it comes to cutting steel. However, only a high-quality water jet cutting machine will provide all these benefits.

There are a lot of water jet machine manufacturers. However, while most of these machines will do the job, not all will provide the finish quality or performance you are looking for.

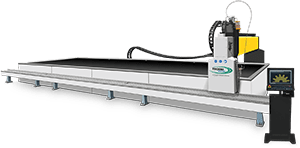

Do you need top performance and quality? Then you need a tried and trusted brand. Techni Waterjet is one such water jet cutter manufacturer, trusted by machine shops in every manufacturing and processing sector.

Techni Waterjet provides you with a wide range of products, and each one delivers what it promises.

The best part is that these water jet cutters come with complimentary software loaded with common cut shapes. You can create these shapes on your workpiece with a click of a button.

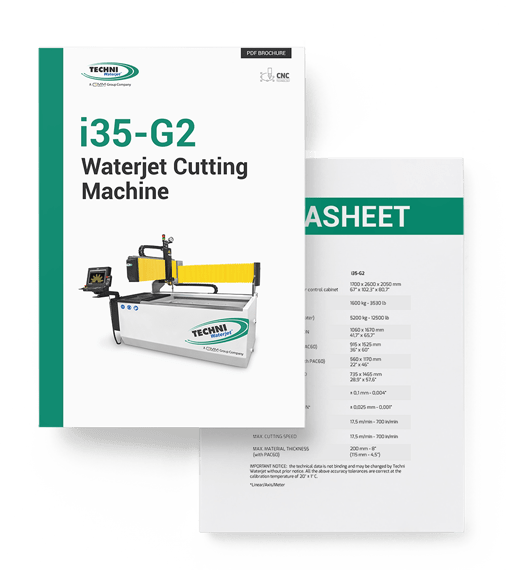

i35-G2

Waterjet Cutting

Machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | 0.1mm - 0.004" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

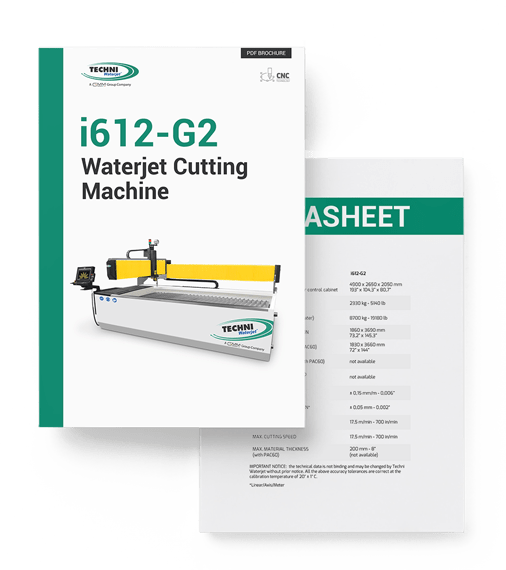

i612-G2

Waterjet Cutting

Machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

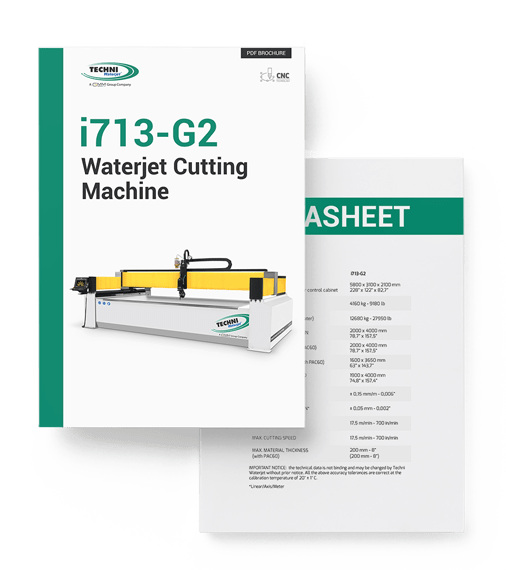

i713-G2

Waterjet Cutting

Machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

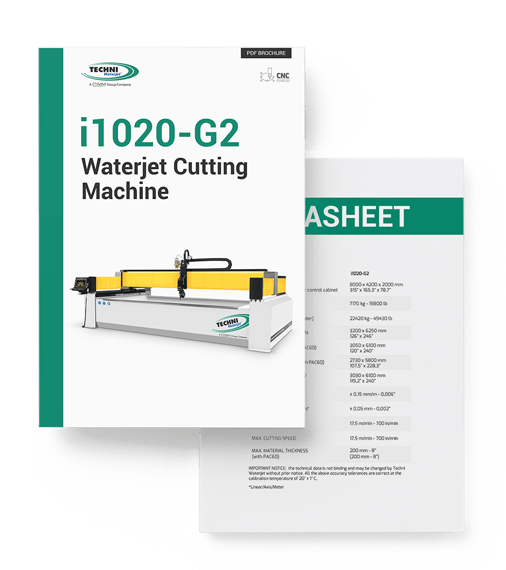

i1020-G2

Waterjet Cutting

Machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

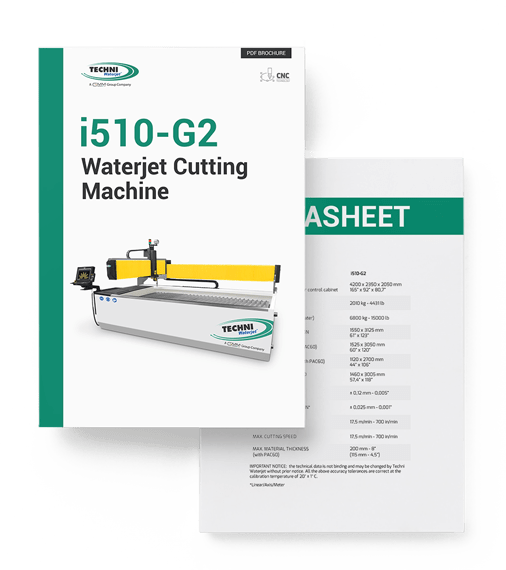

i510-G2

Waterjet Cutting

Machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.12 mm - 0.005" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

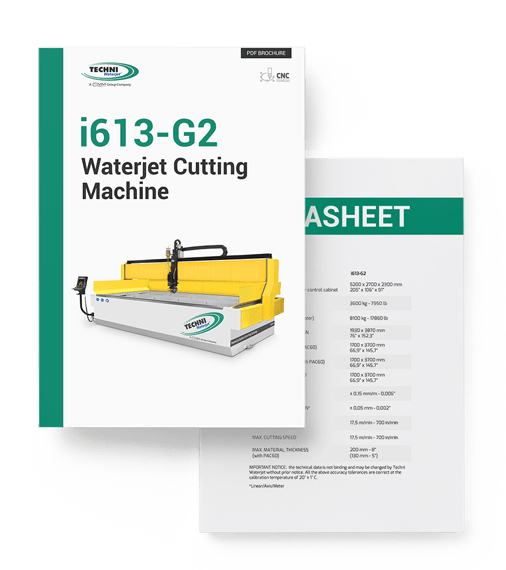

i613-G2

Waterjet Cutting

Machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 130mm - 5" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

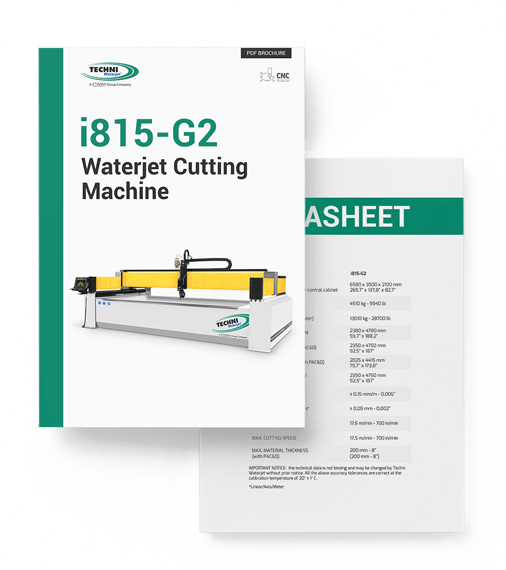

i815-G2

Waterjet Cutting

Machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

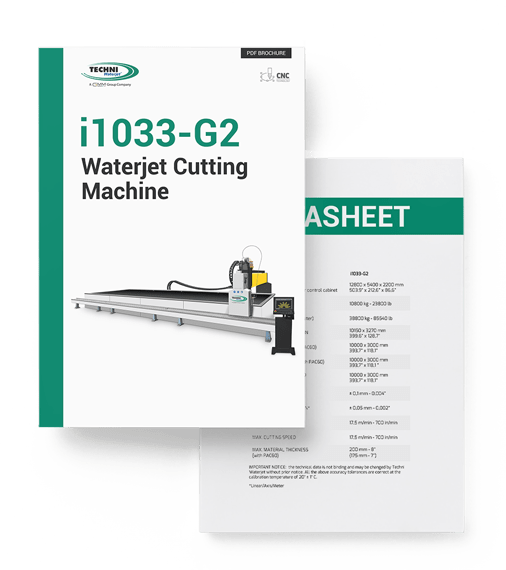

i1033-G2

Waterjet Cutting

Machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ± 0.1 mm - 0.004” |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

Endnotes

Cutting steel with a high-pressure water stream is one of the best ways to achieve exceptional results while saving on material costs and machining costs. There is no worry of material getting ruined and no danger of particles flying around.

The end result is smooth and clean cuts that require no additional processes for finishing. You can use the steel parts as is after the cutting process.

If you are considering cutting options for steel or metal parts, water jet cutting is the best solution. Plus, even if you buy your waterjet to cut steel, you can also use it to cut other materials. Waterjet cutting is ideal for materials like wood, stone, tempered glass (even bullet-proof glass!), and any other material that requires cutting.

Other metals that water jet cutters can be used for include:

Frequently Asked Questions (FAQs)

Here we will answer some common questions that people have regarding water jet cutting of steel:

Can a waterjet cut hardened steel?

Yes, water jets can easily cut hardened steel or tool steel

Can you water jet cut stainless steel?

Yes, you can water jet cut up to 9 inches of stainless steel. An even greater thickness is possible with some advanced abrasive waterjets.