Aluminium is among the most common metals used in manufacturing industries. It undergoes many fabrication processes to make it suitable for different applications.

One such process is cutting aluminium sheets and other components. For this purpose alone, many technology solutions have emerged in recent decades. Among them, waterjet cutting for aluminium has become very popular. But how well does the water jet cutting process perform?

This article explores in detail how water jet cutting works for aluminium, the applications of the process, and how to improve the quality of water jet cutting for aluminium.

Can You Cut Aluminium With a Water Jet?

Yes, in fact, waterjet cutting is the absolute best way to get high-quality results when cutting aluminium.

Aluminium waterjet cutting involves a cutting head that emits a high-pressure jet of water focused on the material that requires cutting. The high pressure of the water jet cuts through the material where it impacts.

When cutting aluminium, an abrasive waterjet cutting process is used. This uses an abrasive material added to the water jet to cut metal faster and easier.

Benefits of Cutting Aluminium With a Water Jet Machine

Many reasons make it preferable to use a waterjet cutter instead of other cutting alternatives like laser cutting or EDM cutting. The benefits of water jet cutting aluminium include:

No Thermal Distortion

Waterjet cutting is a cold-cutting process, unlike other metal-cutting alternatives. In this process, the metal is removed by the sheer force of the water. Therefore, the temperature of the material being cut doe not rise.

The lack of heat-affected zones eliminates thermal distortion in the material, preserving its integrity.

Complex Cut Designs

Waterjet cutting is not limited to two-dimensional cutting patterns. With multi-axis waterjet cutters, creating intricate designs is an easy process.

High-Quality Cutting

Waterjet cutting is used for high-quality machining of parts that do not require any secondary finishing process. One of the main reasons for the appealing finishing is that there are no heat-affected zones, so the material does not get discolored.

Precision Cuts

The jet of high-pressure water used for cutting is tiny, which leads to high-precision cuts with tolerances as low as ±0.005″. There are very few other cutting processes that can achieve such high accuracy.

Unlimited Thickness

Waterjet cutting is unlimited in the thickness of aluminium it can handle. The method applies to cutting solid aluminium blocks and aluminium sheets. Waterjet cutters can handle 12-inch-thick aluminium and up to 9 inches of stainless steel.

Environment-Friendly

Waterjet technology is a green manufacturing process. The cutting is a closed loop mechanism, so all the water used in the process gets recycled. Even the abrasive material can be collected and used over and over again.

Versatile

One of the advantages of an abrasive waterjet cutter is it can be used on a wide range of other materials; for example, stainless steel, carbon steel, copper, brass, titanium, alloys, and more. In most cases, you can use waterjet cutting technology for materials like wood, stone, paper, glass, rubber, and plastics.

Use Cases

Waterjet-cut aluminium is used in a lot of different applications, such as:

- Furniture: Aluminium is one of the most common metals used for making furniture like tables and chairs. A waterjet cutter makes quick work of cutting aluminium sheets and other components into the required shapes.

- Roofing: Aluminium sheets can be cut to form temporary roofs.

- Foil: Since waterjet cutting is a no-contact hygienic cutting process, it is safe for cutting aluminium foil for food products when used without an abrasive.

- Insulation: A water jet is ideal for cutting thin aluminium sheets used for making insulation and ducts.

- Kitchen Utensils: Water jet cutting of thicker aluminium sheets can make kitchen utensils like pots and pans.

- Construction: Cutting aluminium sheets to make siding for construction projects is simple with a waterjet cutter.

- Art and Decor: A custom waterjet setup is so precise it can etch different patterns on aluminium sheets. This makes it ideal for many art and decor projects.

Various types of aluminium are used in many applications. Water jet cutting can handle all grades of aluminium.

- Alumold Aluminium

- Versatile 6061 Aluminium

- Cast Aluminium

- Fatigue Resistant 2021 Aluminium

- Sturdy 5052 Aluminium

- High Strength 7075 Aluminium

Important Tips To Get the Best Quality Results When Waterjet Cutting Aluminium

There are a few things that you can do to improve the quality of the results achieved when using waterjet technology for cutting aluminium.

- Like most cutting methods, a water jet cutter can be noisy. It is best to use underwater cutting to reduce the noise generated when cutting aluminium.

- High-quality Techni Waterjet cutters support this feature with an underwater cutting table.

- When cutting aluminium with a water jet, stacking can help increase production speed exponentially. Stacking involves cutting multiple layers of thin metal or soft materials stacked on each other

- Adjust the pressure of the water jet according to the manufacturer’s recommendation. The rating will vary based on the type and thickness of aluminium or other materials.

Getting the Right Water Jet For Your Cutting Needs

To find out which waterjet cutter will fit your requirements best, you should make your decision based on the following factors:

- Pump Pressure: This critical factor determines a waterjet cutter’s capabilities. Pumps with higher pressure can cut thicker material faster. However, higher pressure results in higher operating costs. Read our guide on how to choose a waterjet pump for more details.

- Budget: Budget is crucial to consider when opting for water jet machining. Prices vary considerably, so find out how much money you will need for the initial investment and setup of a waterjet cutter.

- Software Control: Most waterjets nowadays come with CNC control features. Machining material is possible without manual intervention, running the appropriate software from a computer.

- Cutting Axes: The cutting axes reflect the complexity of design that a machine can create. Intricate 3D designs require a waterjet machine with more cutting axes than for making simple 2D cuts.

Which is the Best Water Jet To Buy?

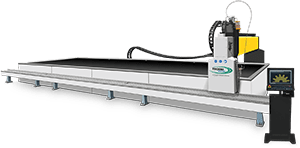

Considering all the critical factors, Techni Waterjet is the industry gold standard when it comes to water jet cutters.

Not only are these cutters feature-rich, but they also come at various price points to suit everyone’s budget. Plus, each machine comes with complementary software allowing easy cutting control from a computer display.

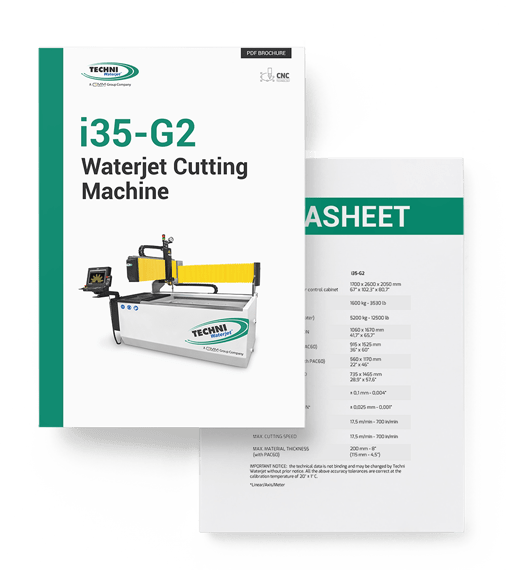

i35-G2

Waterjet Cutting

Machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | 0.1mm - 0.004" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

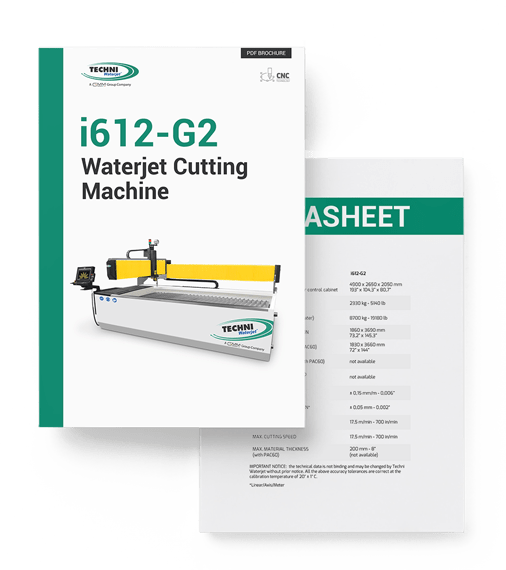

i612-G2

Waterjet Cutting

Machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

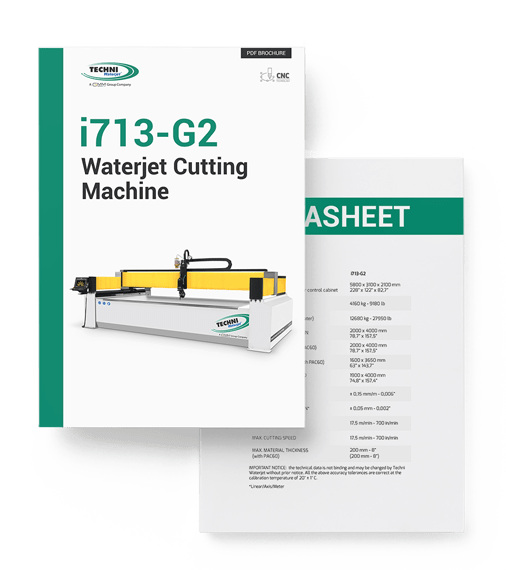

i713-G2

Waterjet Cutting

Machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

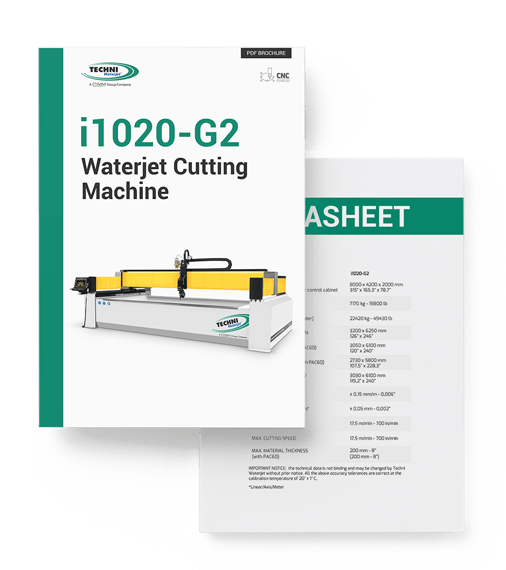

i1020-G2

Waterjet Cutting

Machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

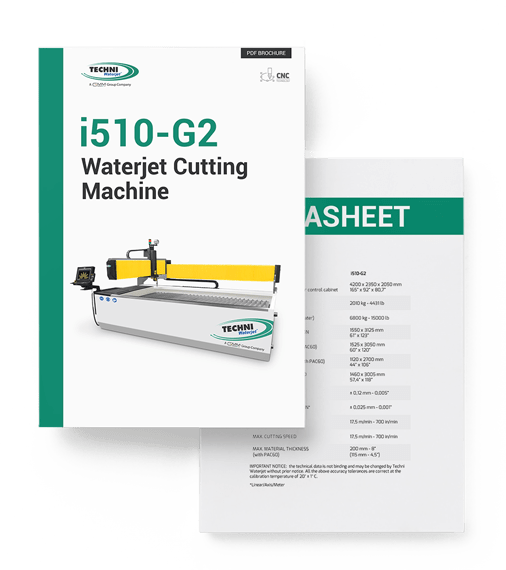

i510-G2

Waterjet Cutting

Machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.12 mm - 0.005" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

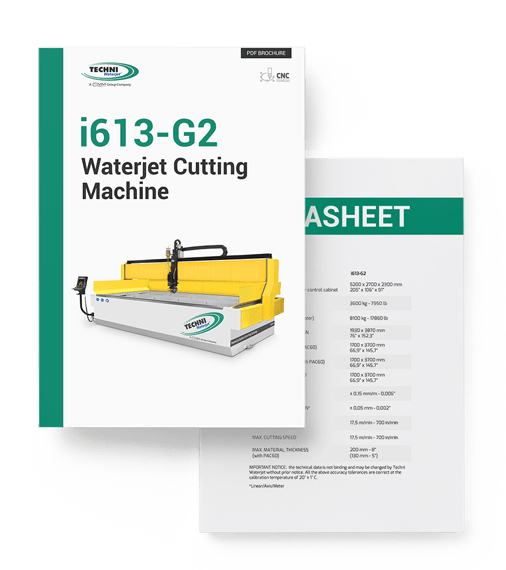

i613-G2

Waterjet Cutting

Machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 130mm - 5" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

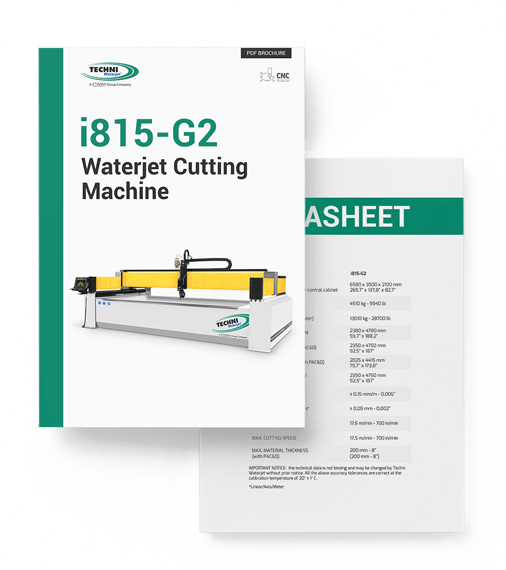

i815-G2

Waterjet Cutting

Machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

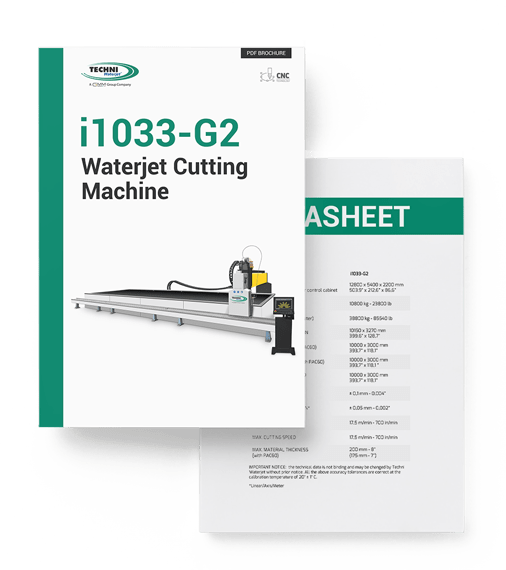

i1033-G2

Waterjet Cutting

Machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ± 0.1 mm - 0.004” |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

Conclusion

Water jet technology is the best solution for cutting aluminium. The advantages make it preferable to laser cutting and other methods, as there are no limitations on the size and type of aluminium a water jet cutter can cut. Cutting a thick aluminium block is just as easy as thin aluminium foil.

And remember, this cutting technology is not limited to just aluminium. You can use a waterjet machine to cut stainless steel, copper, glass, brass, plastic, rubber, and other material.

Therefore, if you are considering adding a water jet machine to your manufacturing production line or workshop to boost production capabilities, go ahead without second thoughts.

Frequently Asked Questions

Here are the answers to some frequently asked questions about cutting aluminium using a water jet:

Will aluminium crack when using a water jet?

No, aluminium will not crack. The ultra-high precision water jet that pierces the aluminium prevents cracking.

How thick can a water jet cut aluminium?

A water jet cutter can go through aluminium as thick as 12 inches. Thicker material can also be cut, but it will take more time.

What pressure is needed for a water jet machine to cut aluminium?

The pressure required can vary from 30,000 psi to 60,000 psi, depending on how thick the aluminium is.

Can you achieve a perfect edge cut with a water jet machine?

Yes, cuts with perfect edges are normal with a waterjet aluminium cutter. A slower cutting speed results in the best finish on the cut edges, without burrs, of the material being worked on.