Welcome To

Techni WaterJet®

TECHNI Waterjet® has officially become part of Biesse, a global leader in the production of lines, machines, and components for the processing of wood, glass, stone, metals, plastics and composites. TECHNI Waterjet® machines have been included into Biesse’s machinery portfolio for metal and feature a refreshed livery, aligned with Biesse brand identity, in a One Company approach.

With Biesse we are set to redefine the possibilities of waterjet cutting technology.

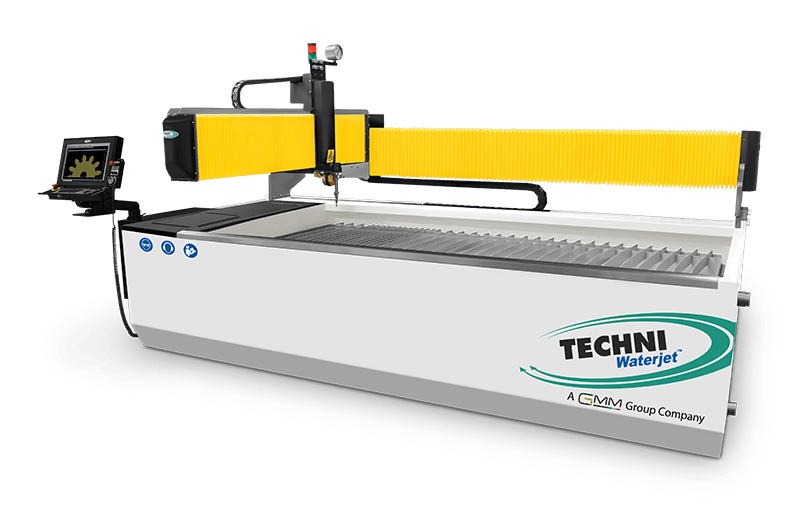

TECHNI Waterjet® is your trusted waterjet cutter manufacturer when it comes to giving your business a competitive advantage using finest abrasive Waterjet machines and cutting technology. Our team of water jet machine engineers has been developing and innovating new complete high-pressure abrasive waterjet cutting solutions for over 35 years.

We pride ourselves on working closely with your business to identify your challenges and provide you with the ultimate water jet cutter for your application. Our highly trained sales team will offer you the support and waterjet cutter you need to ensure your success in generating a high return on your investment.

Search For The Waterjet Cutter You Need

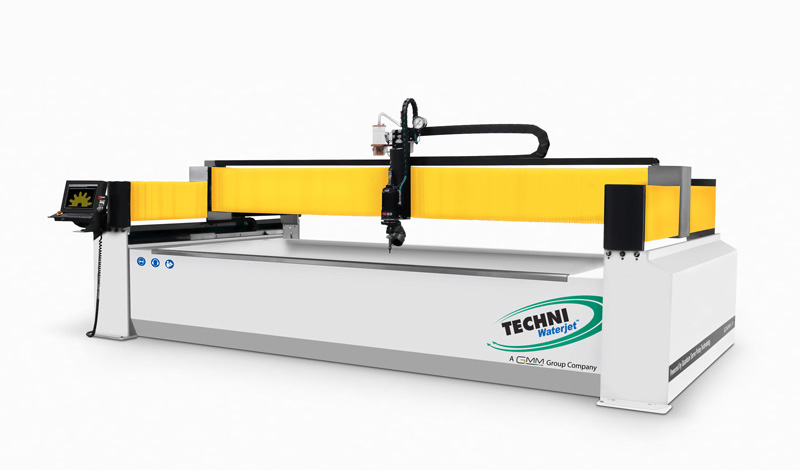

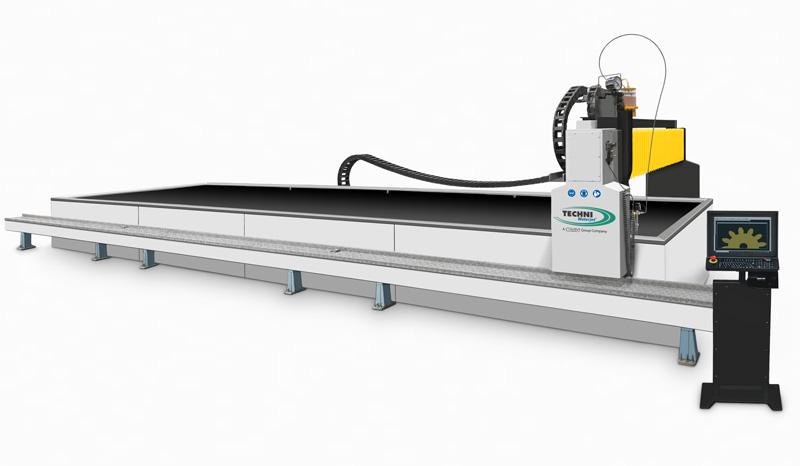

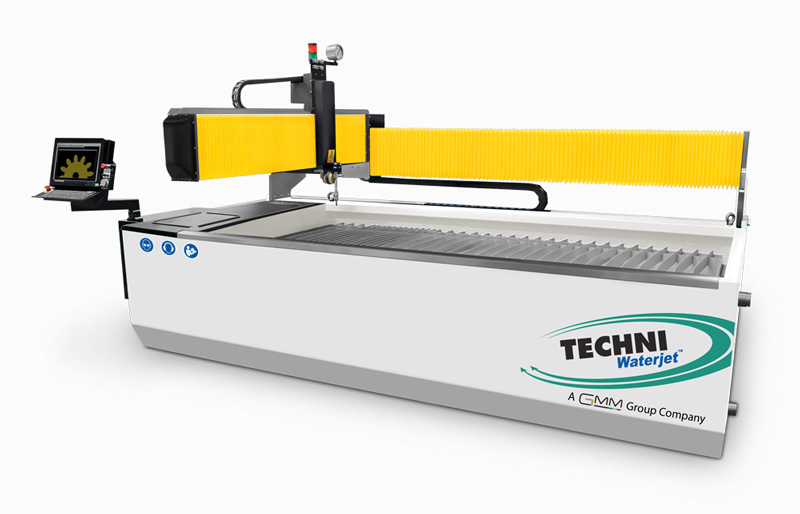

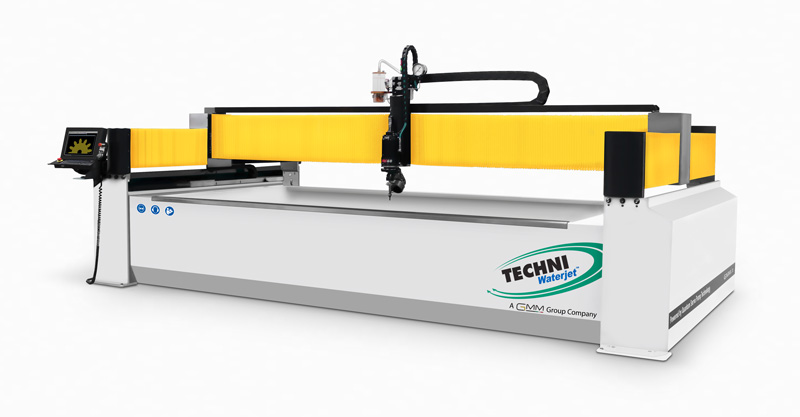

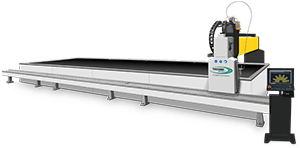

The Intec™G2 waterjet technology allows you to cut even titanium and stainless steel achieving perfect edge quality.

Use our 5-Axis abrasive waterjet nozzle cutters to form parts in almost any material up to 12” – 300mm in thickness.

Our waterjet cutting machines can cut benchtops and worktops, shower screens, window panels, metal signage, fencing, and much more.

Benefits of the Intec™G2 Series Waterjet Machines

Powerful waterjet nozzle cuts parts from stainless steel, granite, plastic and more.

Advanced waterjet technology improves time management for each task

Saves time on finishing due to superior cutting performance

Remote motion control systems program the abrasive waterjet cutting process while you work on other tasks

Our waterjet systems cut multiple materials without changing tooling

No heat zones, no dust or debris, no fumes, no toxic gases, quiet operation

On the Market

Live Demo

We understand that depending on the type of material, customers have different requirements.

This is how Intec™G2 Waterjet cutters deals with them.

AWARDS

Manufacturing Excellence

AFTER PURCHASE: TRAINING & MACHINE SUPPORT

Techni Waterjet® only makes waterjet cutting machines and have done so for 35 years. With a highly experienced and certified team of engineers and technicians we offer our full support throughout the life cycle of your abrasive waterjet machine, to ensure you get the best results and productivity from your investment.

Installation & Training

One on one waterjet technology training during machine set up with our Factory Certified Technicians.

Online Support

This service is successful in nearly 80% of cases, saving customers significant costs in travel expenses and downtime.

Onsite Support

Techni certified technicians provide service and repair assistance for all waterjet solutions whenever you need it.

System Upgrades

We will stay connected with you so that we can provide your water jet cutting machine with the best and latest technology

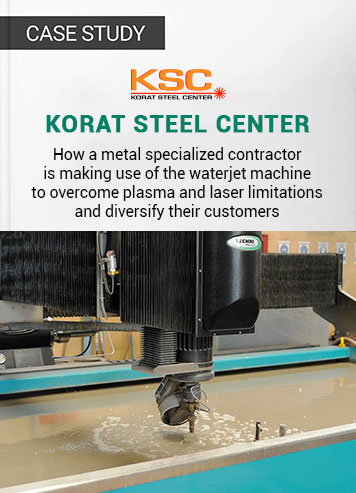

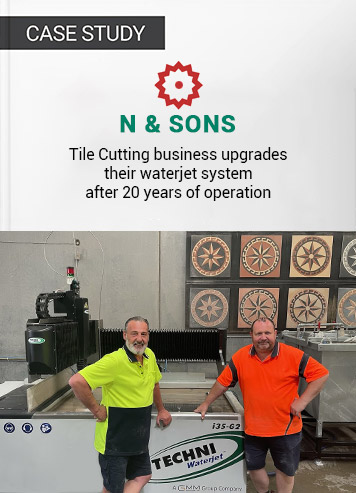

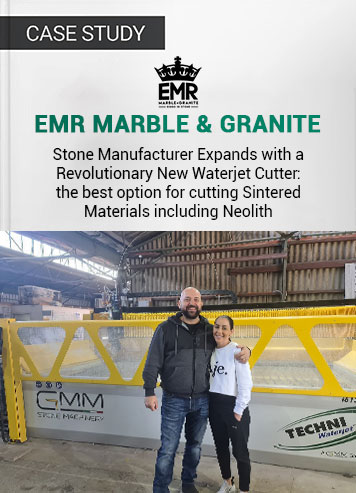

Find Out How Other Businesses Are Using

The Intec™G2 Series

Within Their Workshop

WE ARE AMONG

Global Leaders of

Water jet Technology

Oceania

See AU Office Location

47 Barry Road, Campbellfield,

3061 Victoria, Australia

Americas

See USA Office Location

8610 Air Park, West Drive, Suite 100

Charlotte, NC 28214, United States

Asia

See ASIA Office Location

300/21 Tambol Pluak Deang

Rayong, 21140, Thailand

Europe

See EU Office Location

Zeppelinstraße 7a,

76185 Karlsruhe, Germany

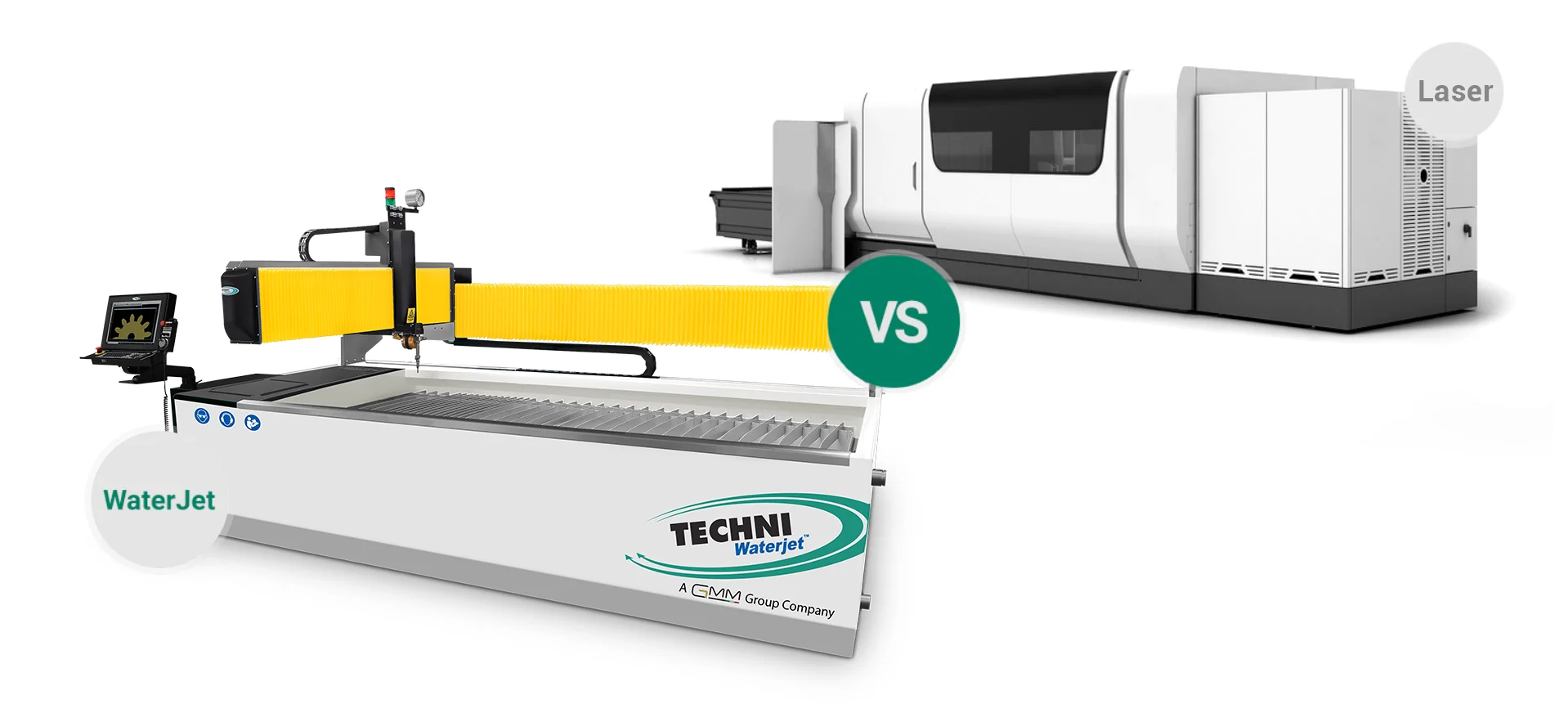

CNC WaterJet Cutting vs CNC Laser Cutting

The Reasons Why You Should Make the Switch To Waterjet Cutting Machines

Shop For Spare Parts

Grab the spare parts you need for your waterjet cutting machine directly from our online store. All parts are Guaranteed to be of the highest quality, ensuring the protection of your investment.

Latest Blog Posts

Waterjet Cutting Glossary

What makes waterjet cutting truly remarkable is its ability to deliver incredibly precise cuts without the heat stress that other methods introduce. The waterjet technology is a clean and incredibly versatile way to shape everything from industrial metals to delicate...

How to Choose the Best Abrasive for Waterjet Cutting?

The appropriate abrasive ensures that the waterjet cuts through different materials precisely, affecting not only the quality of the output but also the cost and speed of operations. Simply choosing a cutter without considering its capabilities can lead to...

What are The Components of a Water Jet Cutter: 28 Parts and Their Function

To understand a waterjet cutting machine, you need to be familiar with how each individual component comes together to cut various materials including metals. A waterjet machine is quite similar to erosion because of the water force it uses. This might still sound a...

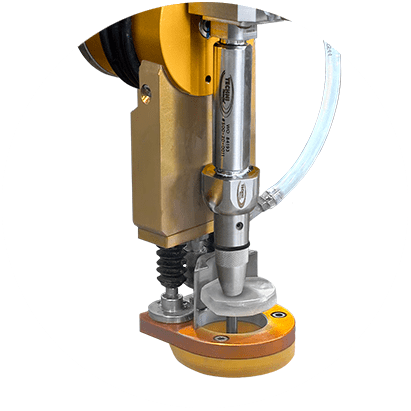

Pac60 Bevel Cutting

Pac60 Bevel Cutting EZY-LOAD Lifter

EZY-LOAD Lifter Abrasive Removal System

Abrasive Removal System Abrasive Pump & Hopper

Abrasive Pump & Hopper Multiple Cutting Heads

Multiple Cutting Heads Skip & Float

Skip & Float Terrain Mapping

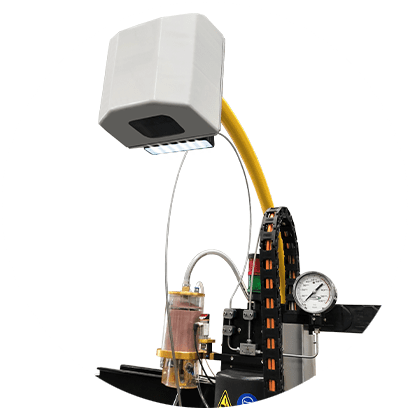

Terrain Mapping Tech Vision

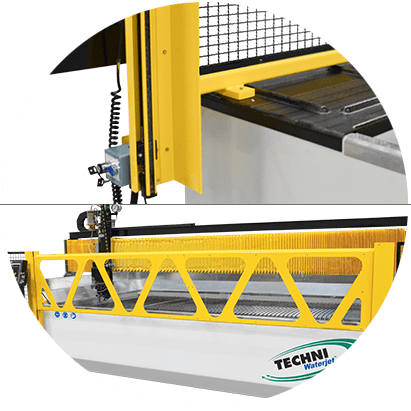

Tech Vision Safety Barriers

Safety Barriers