There is hardly any technology as reliable as high-pressure waterjet cutting when talking about industrial cutting machines. We originally posted an article about the benefits of waterjet cutting and how it performs better than any other cutting alternatives.

In this article, we take the discussion a step further. Many people want to know if waterjet jet cutting wood is possible. So let’s find out if you can waterjet cut wood?

You will find the answer to the question here with other vital information about the subject.

Can You Really Cut Wood With A Water Jet Cutter?

Yes, water jet cutting wood is possible. You can cut thin and thick wood with a water jet cutter. Nowadays, many woodworking applications rely on water jets for cutting wood products.

Water jet cutting is one of the best methods for sizing or shaping wood. This becomes evident when we discuss the benefits of water jet cutting wood.

Main Considerations When Cutting Wood With a Waterjet

Most people don’t realize that you can use water to cut wood, even thick wood. CNC routing for wood has limitations, and plasma, laser, and EDM cutting services can’t handle wood because of its resilience and conductivity. So let us evaluate these considerations in the case of waterjet cutting:

Wood’s Resilience

Wood is a resilient material and will deflect a regular stream of water as used in pure water jet cutting. But abrasive water jet cutting overcomes wood’s resilience and makes an effective cutting solution.

Wood Fracture

Wood is more delicate than metal, so people worry that using waterjets to cut wood will fracture or split the material.

However, waterjets are controlled and focused, especially high-end machines by Techni Waterjet. Therefore, there is no damage to the material.

Jagged Edges

Cutting wood with other methods often results in jagged edges and splinters. Does that happen with waterjet cutting? Absolutely not. Abrasive waterjet cutting utilizes a high-energy, high-pressure stream of water, resulting in a very smooth and even finish.

Water Absorption

One frequently asked question about water jet cutting wood is, “Will wood absorb the water during the process?” While most metals and alloys are resilient to some surface wetness, wood can react quite negatively to it.

However, in the case of waterjet cutting services, the high-velocity stream of water goes through the wood so quickly that there is no time for the wood to absorb it. Therefore, there is no surface wetness, and the wood is still dry.

Benefits of Using a Waterjet to Cut Wood

Now, let’s answer the question, “Are there any benefits of cutting wood with a waterjet?” After all, there is no point in replacing traditional methods with water jet cutting if there are no advantages.

There is no real comparison between waterjet cutting and other alternatives such as plasma and EDM machines. This is because these methods don’t work on non-conductive materials like wood.

Therefore, we will compare waterjet cutting to sawing, the only viable industrial method applied to cutting wood.

Waterjet vs. Saw

To have a better understanding of the differences between water jetting and sawing to cut wood, let us discuss the various parameters that matter:

Finish Quality

With sawing, material removal is accomplished by the friction of the saw blade against the wood workpiece. However, waterjet cutting involves no contact between the tool and the wood workpiece. Therefore, waterjet cutting produces a superior cut quality.

Shape

Using a saw to cut wood works well for straight cuts, but angles and radial cuts are more challenging. However, with a waterjet cutting machine, you just need to hit a key, and you can achieve shaped cuts with ease.

Wood Thickness

Sawing is a difficult process when the wood is of considerable thickness. You need a thick blade with a very high penetration force. However, abrasive garnet mixed with water can cut through thick wood without much effort.

Accuracy

Waterjet cutting is much more accurate than sawing. This is because you can make even minuscule adjustments in position with waterjet cutting by shifting the direction of the cutting stream.

Speed

Cutting wood with a saw is faster than even abrasive waterjets, which take longer to create the same length of cuts. However, keep in mind that the extra time spent gives you a better cut quality with waterjet cutting.

Tips for Cutting Wood With a Waterjet Cutting Machine

As you have already read, computer numerical control (CNC router) waterjet cutters are superior to a saw to cut wood. You can improve the cutting efficiency and quality even more by making use of some tips mentioned here:

Stacking

Cutting a single layer of wood can be slow with a waterjet cutting machine. However, you can stack multiple pieces of wood and cut them together, saving time. This process is called stacking and can also be used for materials other than wood.

Water Velocity and Water Pressure

Water jets can cut even the most delicate materials, wood, and even penetrate plywood without causing ruin to the edges or delamination.

However, ensure safe operation and the best result by adjusting the settings such as speed and pump pressure. You can do this by referring to the user manual. It will give the optimal settings for the specific machine and material.

Knots in Wood

Cutting material like knotted wood is harder because knots have a higher density than the rest of the wood. Knots can take longer to cut, and the grains present can fly around during the process. Take special care when you cut through knots.

Using the Right Abrasive

Abrasive waterjets handle any thickness of lumber and cut precisely. Use the optimal abrasive garnet, and waterjet cutters can cut metal like steel as easily as wood.

Can You Water Jet Plywood?

Plywood contains multiple layers of wood glued together, so people wonder if you can cut it with a waterjet. Using other methods for cutting wood often results in delamination of layered plywood, so it is fair to ask if that happens with waterjet cutters.

Water jet cutting plywood is straightforward. With a waterjet cutter, you can easily cut plywood without delamination or edge damage. Just make sure you use the right water pressure and velocity.

Can You Water Jet Wood With Knots?

The answer to the question “Can you waterjet wood?” is easy. Yes. What about cutting wood with knots? Although a waterjet will cut wood with knots, it can be hazardous due to the wood grains flying around. Additionally, it takes a long time to cut through knots.

As mentioned earlier, cutting wood with knots requires special care with waterjet cutting. For convenience and to maintain the speed of cuts, we recommend that you avoid cutting wood with knots.

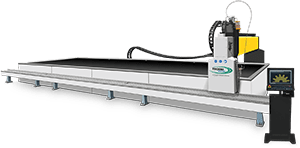

Getting the Right Waterjet Cutter for Wood

All the previously mentioned benefits of water jet cutting wood are applicable only if you choose the best machine for the job. Many folks choose the wrong waterjet cutting machine for the type of work they frequently need to do, which leads to bits of wood breaking off or a delamination problem.

For the best quality cuts, we recommend using Techni Waterjet cutting machines. When it comes to water jet cutters, there is no better setup than that provided by Techni Waterjet.

These machines provide smooth cuts on virtually any type of material and are known for their durable build quality. Therefore, if you need a waterjet cutter for your next project, try Techni Waterjet cutting machines!

Here’s why:

- Can handle a wide range of materials, including hardwood, softwood, veneer, and laminate. This means that you can use the same machine to handle virtually all types of wood without having to invest in multiple tools.

- Highly accurate: you won’t waste material or end up with uneven cuts. This saves you time and money in the long run.

- Easy to operate: Even beginners can start using the machine right away without special training or expensive software.

- Low maintenance: you won’t have to spend a lot of money on upkeep. This makes them a cost-effective option for woodworkers of all budgets.

- Backed by excellent customer service and support – you can be sure that it’s a solid investment.

i35-G2

Waterjet Cutting

Machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | 0.1mm - 0.004" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i612-G2

Waterjet Cutting

Machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i713-G2

Waterjet Cutting

Machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i1020-G2

Waterjet Cutting

Machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i510-G2

Waterjet Cutting

Machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.12 mm - 0.005" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i613-G2

Waterjet Cutting

Machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 130mm - 5" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i815-G2

Waterjet Cutting

Machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

i1033-G2

Waterjet Cutting

Machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ± 0.1 mm - 0.004” |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

To Summarize

Water jet cutting wood using high-pressure waterjet cutters is not only possible but, in fact, the best way to cut many types of wood.

Waterjet cutting provides benefits that no other woodcutting technology can provide. Plus, you can use a waterjet cutter on metal, stone, ceramic, foam, glass, and many other different materials. That makes it incredibly cost-effective in the long run.