Waterjet cutting is by far the best development in industrial cutting technology. From cutting stone to softer materials, a high-power water jet cutting head nozzle can cut through virtually anything regardless of the thickness.

Benefits such as quality, precision, and cutting speed make the waterjet cutting method popular.

But what about waterjet tile cutting? Is it possible? In this article, we will answer the question: can you cut tile with a waterjet?

You will learn the basics of waterjet tile cutting, its benefits, and some tips to get the best results from the cutting process.

Can You Cut Tile With a Water Jet?

Definitely. Water jet cutting can not only cut tiles; it gives you the best results. In fact, a waterjet cutter can handle any type of tile you use.

Benefits of Cutting Tiles With a Water Jet Machine

Why should you use a waterjet cutting system for tile instead of another method? Here are some of the benefits:

High-Quality Cutting

A waterjet tile cutting system produces a smooth finish on the cut edges of the tile. Most other methods can’t achieve this. With tools using blades, the rough tile edges need a secondary finishing process.

However, when cutting with a waterjet, the edges are so smooth that you don’t have to invest time and resources in secondary processes.

Versatile

Waterjet abrasive cutting handles any type of tile; no need to change the tooling to cut a different type of tile. This makes waterjet tile cutting a very versatile process.

Automatic Cutting

Waterjet cutters are controlled with a CNC machine that makes the process automatic. So there is no need to manually handle the cutter or the tile while cutting. Everything can be adjusted and run with computer programs.

High Production Rate

Waterjet abrasive cutting can speed up the tile cutting process. You can stack multiple tiles on top of each other. Since the entire process is automatic, you can save considerable time and labor.

Cold Cutting Process

Waterjet cutting is a cold cutting process, very different from laser cutting and other methods. In hot cutting processes, the temperature rise can lead to distortion of edges and other damage.

However, a waterjet cutting system doesn’t increase the temperature of the tile. So there is no heat-affected zone and no damage.

Recyclable

Waterjet cutting is a closed loop process, and you can recycle everything, from water to abrasives. This is helpful for the environment and reduces the costs of new raw materials.

What Types of Tile Can You Cut With Waterjet Cutting?

The waterjet tile cutting process can work on a wide variety of tiles. Some are listed below:

- Marble tiles

- Ceramic tiles

- Porcelain tiles

- Granite tiles

- Metal tiles

- Limestone tiles

- Cement tiles

- Mosaic tiles

- Travertine tiles

- Stone tiles

- Quarry tiles

- Glass tiles

Waterjet cutting is viable for so many types of tiles that tile fabricators use this process for various applications. Some of these applications are:

Floor Tiles

When cutting floor tiles, aesthetics and finishing are important factors. Therefore, waterjet cutting is the preferred cutting process since it can create very smooth edges without any damage.

Kitchen Tiles

Tile fabricators require a clean and hygienic cutting method for kitchen tile cutting. Waterjet tile cutting fits the criteria perfectly. In addition, it is possible to create a lot of different cuts with this method.

Commercial Areas Tiles

In commercial areas like malls and office buildings, tiles are used for flooring and decoration. Additionally, tile cutting needs to be fast and done with high precision. Waterjet tile cutting is the go-to choice for commercial tile fabricators.

Counter Tile

Counter tiles are generally thicker slabs that require a robust cutting process. Abrasive waterjet tile cutting can easily handle tiles of all sizes.

Fireplace Tiles

Fireplaces often use hard stone, ceramic, or porcelain tiles. Other cutting alternatives like laser cutting either don’t work or take a long time cutting the entire length. Abrasive waterjet cutting easily handles cutting stone and tiles for a fireplace.

Tips For Cutting Tiles With a Waterjet

It’s easy for a waterjet to cut through tile. However, for the best results, here are our top tips that you can follow:

Stacking: Instead of cutting one tile at a time, stack multiple tiles on top of each other. Doing this results in a high-speed cutting process.

Support: Provide robust support when cutting stone/tile to prevent cracking the stone/tile.

Proper settings: Manufacturers of waterjet cutting machines provide detailed instructions to cut various materials, so ensure you use the recommended settings for tiles.

Recycling: When using abrasive cutting, you can recycle the water and the abrasive. Use a proper recycling process such as a strainer to collect the abrasives and use them again to save costs.

Control System: You don’t have to oversee the entire cutting process. You can load the required model in the software for simple cuts, such as single-line cuts. Techni Waterjet’s cutters come with complimentary software with preloaded cutting designs.

Low-Pressure Cutting: Don’t just use the highest pressure setting for all materials. It can lead to cracking delicate materials like marble, glass, ceramic tile, and porcelain tiles. Use low-pressure water jet cutting to create partial cuts in these materials.

Etching/Engraving: You can also do etching on various tiles and glass with a water jet cutter. For this purpose, you need to cut at high speed with low pressure.

Abrasive size: When cutting ceramic tile, it is a good idea to use finer abrasives. Additionally, the hardness of the abrasive should be more than that of the tile itself. Hard abrasives like aluminum oxide (commonly called corundum) are ideal when cutting hard ceramics.

Getting the Right Water Jet For Tiles

A waterjet cutting machine is a significant investment. Therefore, you need to choose the right one. Some important factors to consider are:

Adaptability

The waterjet cutter you choose should be able to cut tiles of different sizes, materials, thicknesses, and chemical composition. Switching between different types should be seamless.

Performance

You need a machine that can provide excellent results. A good machine will cut a lot of material in the least amount of time without compromising cut quality or precision.

Durability

Waterjet cutters must handle extremely high water pressure. Therefore, the construction and parts should be robust to avoid breaking down often. Consumables like rubber seals are cheap to replace but replacing bigger parts can cost thousands of dollars.

Support Services

There should be after-sales support from the water jet manufacturer in case of a fault or any other technical query in the long run.

Features

Cutting tiles is not limited to straight line cuts. Sometimes, operators may need to engrave or cut intricate designs. Therefore, the machine should support these functions for ceramic tile, stone tile, and other materials.

Usability

A waterjet cutter can cut more things than just tiles, such as plastics, wood, metals, and more. If you are buying a waterjet cutter, you might want to invest in a machine that can handle other materials too.

Best Waterjet Cutter for Tiles

Based on these factors, most professionals prefer water jet machines from Techni Waterjet. Techni Waterjet is one of the leading water jet manufacturers, trusted by workshops that value quality results and the advantages offered by our machines.

Our CNC waterjet cutters are rugged and can withstand any environment in which they operate. They are also built to last longer than alternative water jet cutters.

Plus, with Techni Waterjet, you get personalized service and complimentary software with preloaded cutting designs.

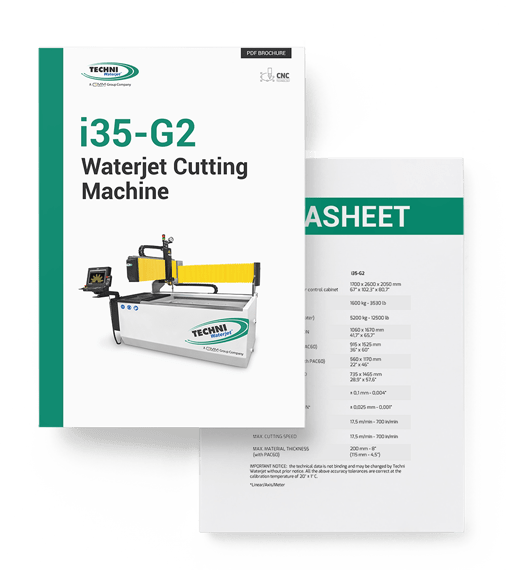

i35-G2

Waterjet Cutting

Machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | 0.1mm - 0.004" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

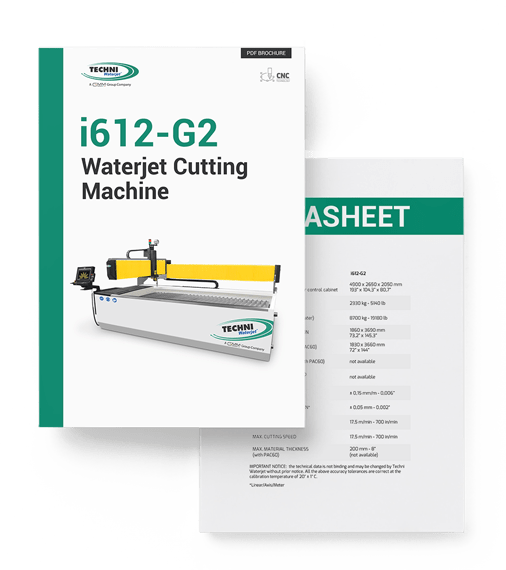

i612-G2

Waterjet Cutting

Machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

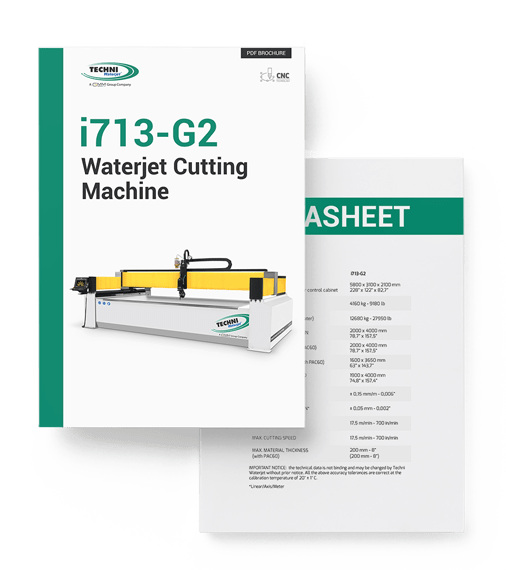

i713-G2

Waterjet Cutting

Machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

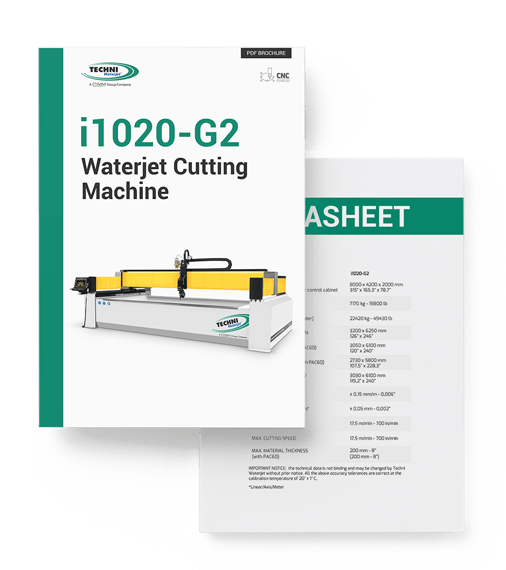

i1020-G2

Waterjet Cutting

Machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

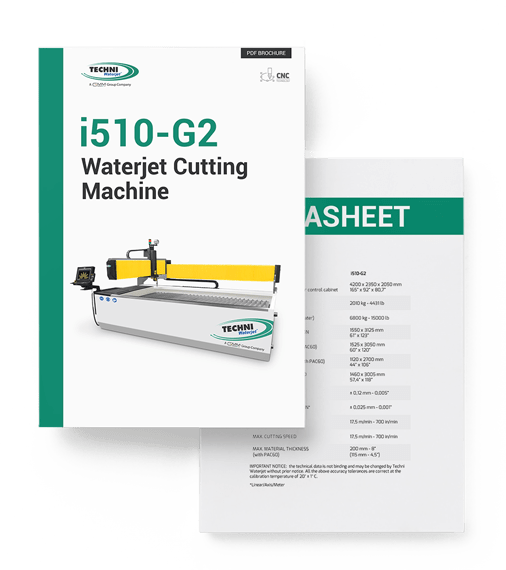

i510-G2

Waterjet Cutting

Machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.12 mm - 0.005" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

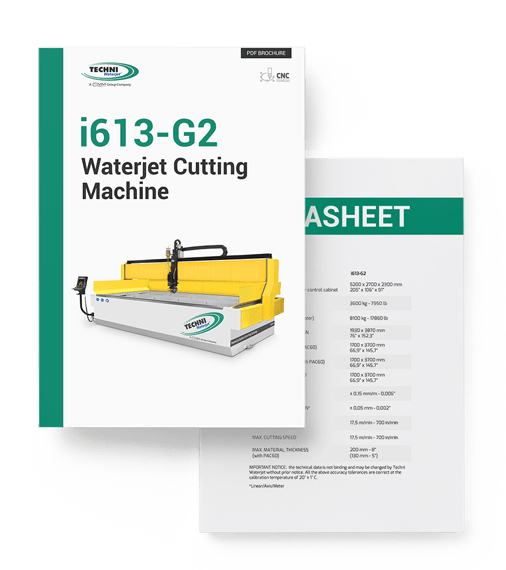

i613-G2

Waterjet Cutting

Machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 130mm - 5" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

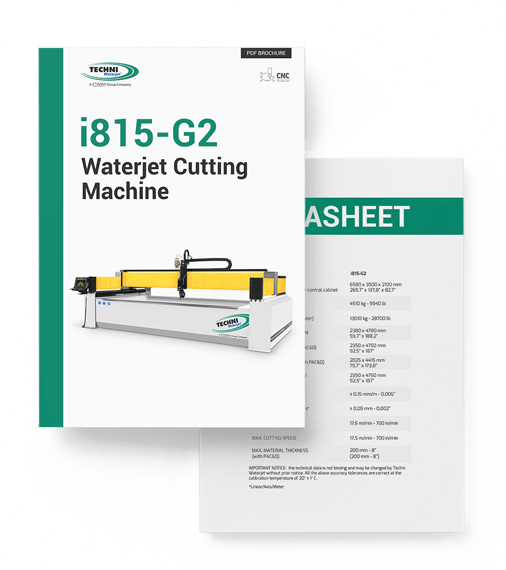

i815-G2

Waterjet Cutting

Machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ±0.15 mm - 0.006" |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

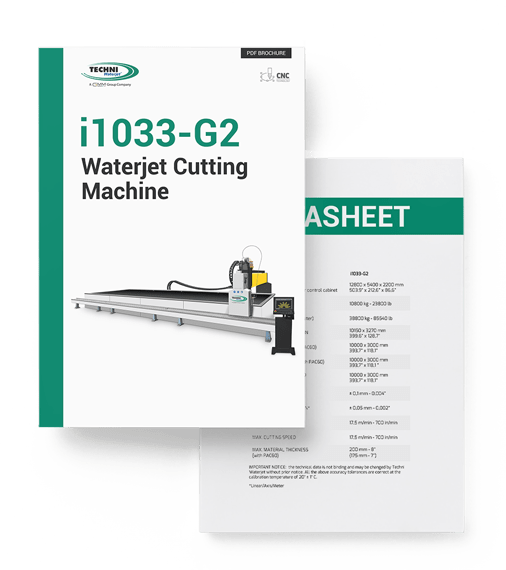

i1033-G2

Waterjet Cutting

Machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Gantry |

| Accuracy of Motion (Linear/Axis/Meter) | ± 0.1 mm - 0.004” |

| Max Material Thickness | 200mm - 8" |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

| Brochure | Download |

Key Takeaway

The process of waterjet tile cutting is the top choice for many tile fabricators due to its quality and effectiveness. Are you wondering whether or not you should go ahead with a water jet cutter for tiles? You should not doubt that tile cutting using a water jet is a perfect solution.

FAQ

Here are the answers to some commonly asked questions regarding waterjet cutting for tiles:

Can you waterjet a porcelain tile?

Yes, waterjet cutting works for all tiles, including porcelain tiles. It also works for many other raw material.

Will the tile crack when using a waterjet?

No, tiles do not crack with a waterjet. You just need to ensure you use the recommended pressure settings, nozzle, and cutting head. Also, arrange adequate support for the tile while cutting it.

Can you achieve a perfect edge cut with a water jet machine?

Yes, with the correct nozzle, you can cut perfect edges with a water jet machine.